As Taharka Brothers Ice Cream CEO Stephen Butz saw restaurants in Spain and France shutting down amid the spread of the COVID-19 pandemic last week, he knew closures would soon be coming to the U.S.

The Hampden-based company, which, along with the smiles elicited by ice cream, is known for bringing social engagement and local employment, typically does 65% of its business selling wholesale tubs to restaurants and other retail locations, so it knew continuing on as other restaurants closed and continuing to keep its roughly 10 team members onboard would require change.

That meant a shift in its model to a direct-to-consumer approach. Specifically, home delivery — which is still allowed despite restrictions the order that restaurants close. The thinking was this, Butz said: “If we spin our business to pint production only, can we create a new source of demand and actually get the numbers so that held us in a state where we could pay everybody?”

But it was also necessary that they made change quickly, and tech ended up being key to that shift. Canton-based application developer Adam Douglass worked with Taharka Brothers to create a web application where customers could order cases of ice cream, and the company could manage deliveries.

On Friday and Saturday, they met with Canton-based software developer Adam Douglass, with whom they had worked in the past, and described what they needed.

“I went off into my basement and worked through the night and over the weekend to wire up a home delivery system,” Douglass said.

By Sunday, the delivery service was launched and delivery started on Monday. It quickly started to spread on social media, and now the factory is humming.

“We made double the amount of pints we’ve ever made in response to this,” Butz said Tuesday, in the midst of another busy day of orders.

https://www.facebook.com/TaharkaBros/posts/10158036416924770?__xts__[0]=68.ARD6shhMQjVKjU-wuhxGtZyu5J-7xaUl6a0SAhjND0ZPZfGuv5V09Mzp71YfuBEYq8FLWFasAFMX6vWbZfJgw9CJbHGPIUTZNRDxNysYaFXjmtZ4ApRzlHMv-vLJKN6jonVLCdZQOisDVQ_CyHUkvZFnO6nvm6ynjetIwcPrIurui1ZHNs-l4pCPo0XsZ1-AncK9LkCe-UcuqxNVr4FvGgKDLjghR3F5HD8zMhKJ-BfBZ0xUOtUWwwzjQQk7VsQzrJj8vYDIp6_saoJCedFrLXsdmUWMAGQ6MWSzWtiXmarutGEmwBpV7zljejApoXcqseT1stsyBXjHqUfkpQ&__tn__=-R

The new mode allows Taharka to keep making ice cream at the Hampden factory, but it is packaged in pints. To ensure the ice cream stays cold, customers must order a case to be delivered, which is eight pints. Right now, there’s no delivery fee.

The frontend allows customers to type in their address, and see whether they fall into the delivery zone of the Baltimore metro area. If they’re in it, they can build an order with different flavors in a case, and pay via credit card. Finally, they receive a text message to confirm and when the delivery is scheduled. After all, it’s especially important that customers are home to receive.

“They have to be there. Otherwise it’ll melt,” Douglass said.

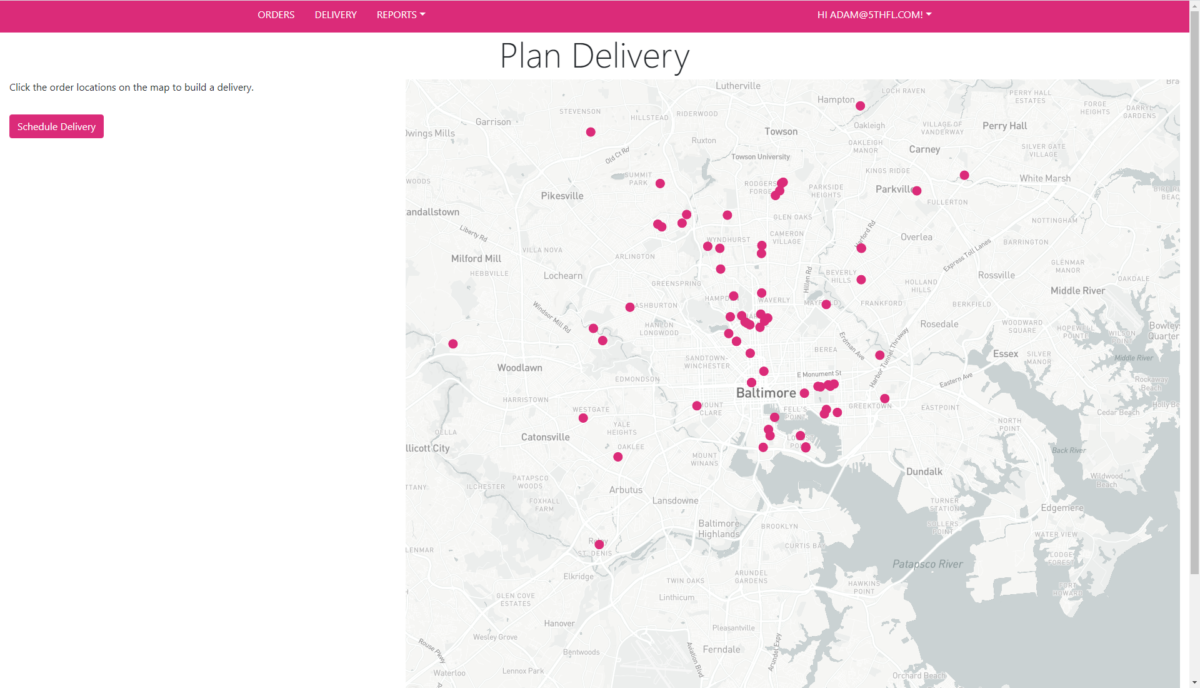

On the backend, the Taharka team can see delivery locations on a map (complete with on-brand pink dots) and plan routes accordingly by drawing on map. It also allows for production planning based on the orders that are coming in, which is important given the shift to pints.

“The technology is so helpful,” Butz said. In another bit of good timing, Taharka also purchased a new delivery truck in the last three months that’s now being put to use for direct-to-consumer.

Douglass said he built the system in .NET, and used Twilio for texting. Slack is also key to the operation: The system sends messages to a Taharka Slack channel when an order comes in, and there’s a channel that allows for texting.

As the new realities are forcing businesses to adapt, it shows how technology enabled quick change. As Douglass put it: The tech allowed for a product that wasn’t offered on a Friday to be offered on a Monday.

Before you go...

Please consider supporting Technical.ly to keep our independent journalism strong. Unlike most business-focused media outlets, we don’t have a paywall. Instead, we count on your personal and organizational support.

3 ways to support our work:- Contribute to the Journalism Fund. Charitable giving ensures our information remains free and accessible for residents to discover workforce programs and entrepreneurship pathways. This includes philanthropic grants and individual tax-deductible donations from readers like you.

- Use our Preferred Partners. Our directory of vetted providers offers high-quality recommendations for services our readers need, and each referral supports our journalism.

- Use our services. If you need entrepreneurs and tech leaders to buy your services, are seeking technologists to hire or want more professionals to know about your ecosystem, Technical.ly has the biggest and most engaged audience in the mid-Atlantic. We help companies tell their stories and answer big questions to meet and serve our community.

Join our growing Slack community

Join 5,000 tech professionals and entrepreneurs in our community Slack today!

The person charged in the UnitedHealthcare CEO shooting had a ton of tech connections

From rejection to innovation: How I built a tool to beat AI hiring algorithms at their own game

The looming TikTok ban doesn’t strike financial fear into the hearts of creators — it’s community they’re worried about