Delaware Libraries have been closed to the public for weeks, but at the Route 9 Library and Innovation Center in New Castle, the large 3D printer and laster cutter are up and running, churning out plastic face shields for 3D for COVID. The national collaboration of makers, with an East Coast hub at Synergy Mill in Greenville, South Carolina, collects 3D-printed face shields and parts for sterilization and distribution to hospitals with most need.

As a shortage of masks for healthcare workers became apparent with the rise of COVID-19, Jessica Glassco, makerspace coordinator at the Route 9 Library, was asked by the Delaware Division of Libraries (DDL) if the libraries could help make PPE. With the assistance of DDL Emerging Technology Specialist Nickolas Martin, she began researching designs for masks which could be used by medical professionals in the field.

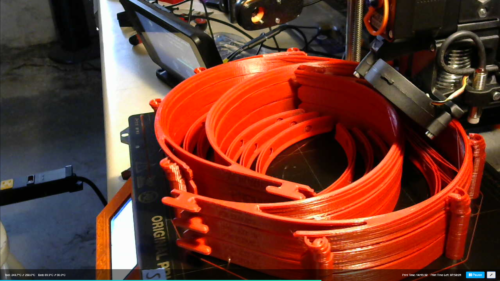

“In evaluating options, we determined that while the existing equipment was unable to manufacture N95 masks for medical use, it could be used to make a combination of sewn mask and 3D printed/laser cut plastic face shield,” Glassco told Technical.ly. “With additional research, I selected the design by [Czech Republic 3D printer company] Prusa Research that consists of a headband, clear shield, bottom reinforcement and elastic band.”

While Glassco, who had to submit a proposal for the project in order to be approved to enter the library (which has an operating police substation on site) during the shutdown, oversees the printing in the maker lab, collaborators Jonathan Rudenberg and Daniel Siders, founders of the Newark software startup Flynn, offered to coordinate the logistics of delivery.

“They pick the parts up from the makers and send them together to 3D for COVID,” she said.

Right now, one local maker, Chris Elliot, is producing parts at home, and the partners are hopeful that others with home 3D printers join in on the project, which is funded by DLL, plus a filament donation by Flynn.

“As long as your printer bed can fit a 199-millimeter-by-202-millimeter print, you can print a headband,” Glassco said. “There are stacked designs available, so you can print many at once. If your printed bed can print 236 millimeters by 203 millimeters, you can do two stacks at once. The designs are being tested across the globe and improved all the time. Smaller printers can do the bottom reinforcements for these designs.”

The Delaware collab has submitted several variations to ChristianaCare for approval; so far, the health system has approved a headband, with an approval for the face shield material pending.

While they are supplying the face shields to Delaware nursing homes, most the the face shields at this point are going to hospitals and care facilities out of state, simply because the highest level of need is in other states.

“I hope it doesn’t turn people off that we’re sending them [out of state], but we believe sending them to where there is the most need will do the most good,” Glassco said. Of course, when ChristianaCare approves the shield material, the local partners will provide face shields to the healthcare system as requested.

Feedback on the designs, and the ability to improve upon them, is one of the crucial aspects of using 3D printing for making PPE.

“It’s a cool example of what 3D printing is about: making prototypes and adjusting them until you get it right,” Glassco said.

Eventually, she said, the face shields will likely be made into injection molds and mass produced, lessening the need for individual makers to fill the gap in the availability of a product that was previously used primarily in dentist offices.

For now, though, makers are encouraged to join if they have the equipment. The group has a Slack channel to discuss the latest info with local and global contributors. Participants will need to know specific specs before printing, such as what type of filament and other materials are required (and where you can get them, including Printed Solid in Newark). For an invite to the Slack or more information about the project, email Rudenberg at facesheilds@titanous.com.