As COVID-19 spreads, the availability of ventilators that can help keep getting much-needed oxygen to patients having trouble breathing is being closely tracked.

Before a patient can be placed on a ventilator, a process called intubation must be performed to insert a tube into the mouth and the airway. To do so, doctors must place their fingers on the patient’s gums to open the airway.

Describing the work to The Washington Post’s Eli Saslow, a Chicago anesthesiologist called it “probably the most dangerous procedure a doctor can do when it comes to personal exposure.”

As the virus at the center of the global pandemic was spreading in March, that risk prompted an urgent call from the wife of a doctor in California to Baltimore County’s Shore Plastics. It was the beginning of a new role in COVID-19 response for the custom plexiglass fabricator and supplier that has been in the Baltimore area since 2013.

Frightened for her husband’s safety as protective equipment shortages began to mount, the woman discovered a design for Aerosol Boxes, invented by Dr. Hsien Yung Lai of Taiwan and available via Creative Commons license. She asked Shore Plastics to make the acrylic units that provide protection at the point when there is highest risk.

“These boxes are used, especially with low levels of PPE for doctors, to help control the amount of body fluids and germs that can pass during the intubation process between patient and doctor,” said Randy Shore, who is the son of Shore Plastics owner Larry Shore and manages the company’s web and Google presence. “In addition, these boxes are meant to be cleaned and re-used for the next patient to ensure that hospitals only need a few of these and shortages don’t occur.”

1/ Well, today has been interesting. Never thought that my dad's plastic company, @ShorePlastics, would have anything to do with helping to solve #COVID19. Turns out, thanks to an invention by Dr. Hsien Yung Lai, theres a need for acrylic #AerosolBoxes to protect Drs.

— Randy Shore (@RandyShore) March 29, 2020

With Randy Shore setting up a new website and Google AdWords campaign, orders began to come in from around the country from states like Wisconsin, California and Michigan. Larry Shore realized there was not only demand, but a need for a fabricator that the firm could fulfill.

Working to get them into the hands of doctors to help flatten the curve as the number of COVID-19 cases climbed toward their peak, the company partnered with Baltimore-based Quake Scientific and determined that they could make the Aerosol Boxes with a process that required just a single piece of plexiglass. It allowed the boxes to be produced and shipped in the same day.

But getting the product out to the people who needed it wasn’t just a matter of production. When it came to fulfilling orders, there would also be demand on the tech side to facilitate.

“We began by incorporating the product into the Quake Scientific Shopify store to allow self-service access to these boxes by anyone in the U.S., taking care of payment and shipping calculations,” Randy Shore said. “In order to prevent breakage, we determined that shipping these in pairs would allow them to be strong enough to ship nationwide. Quake also had the support staff and ability to add additional production staff, at a time when they may have otherwise been furloughed, to keep up with the demand.”

The staff is practicing social distancing, he added.

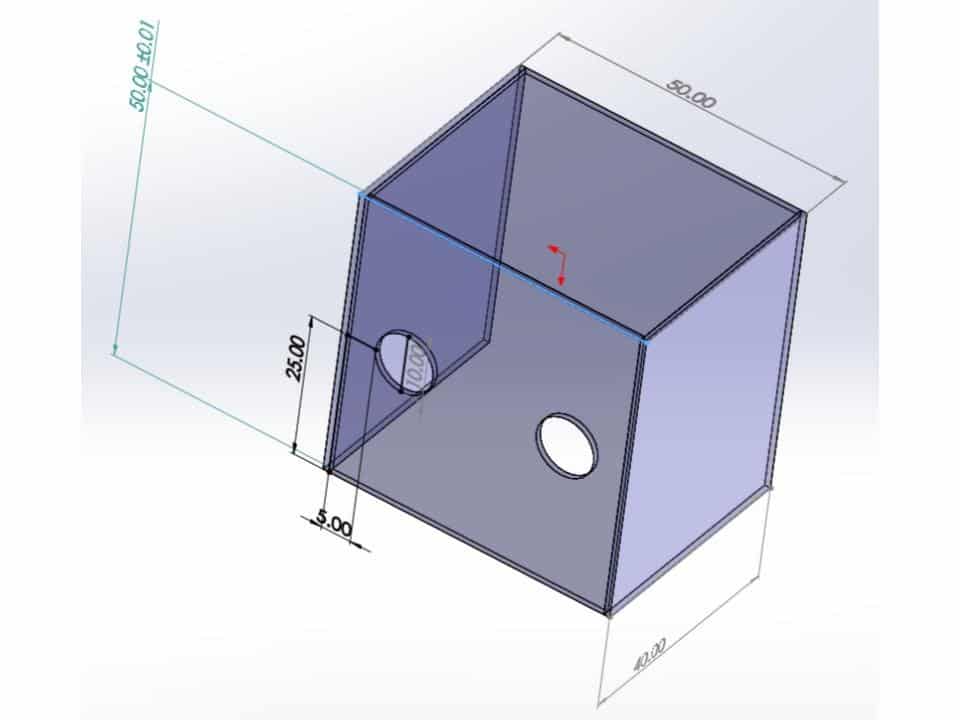

For protection, doctors insert their arms into the holes in an aerosol box, shown above. (Photo courtesy of Shore Plastics)

There were also lots of other calls coming in — from customers who wanted more info, to citizens who wanted to contribute to the cause. In his primary role as VP of delivery and support for cloudtamer.io, a Fulton-based a cloud governance solution that manages accounts, enforces budgets and automates compliance for cloud workloads in AWS and Azure, Shore came across a product that might work: Amazon Connect, which offers “contact-center-as-a-service” for firms seeking customer service solutions.

On a Sunday afternoon in late March, he figured out how to set up a call tree that would route calls to either Quake Scientific’s staff, or Shore Plastics.

“Within about 30 minutes, my wife had recorded the voice prompts, calls were routed based off the user selection, and we streamlined the process to get people information about the boxes in the most efficient manner,” Shore said. “As small as it seems, its amazing how easily one can get anything-as-a-service nowadays thanks to the power of AWS. By Sunday evening, the phone tree was live and kicked into gear.”

By the end of the week, they were moving production into hundreds of units a day.

Hearing the story, it struck this reporter that these are the same kinds of approaches that are at the heart of bringing new products to the world, even when there’s not a global pandemic. The company found demand for a product and figured out how to produce it, partnered to add value and sought outside resources that could help make things more efficient.

But in this case, they’re moving even faster than even the typical “speed of innovation,” and the goal is to save lives.

This editorial article is a part of Technical.ly's Healthcare Technologies Month of our editorial calendar.

Join our growing Slack community

Join 5,000 tech professionals and entrepreneurs in our community Slack today!

Donate to the Journalism Fund

Your support powers our independent journalism. Unlike most business-media outlets, we don’t have a paywall. Instead, we count on your personal and organizational contributions.

Comcast introduces ultra-low lag Xfinity internet that boosts experiences with Meta, NVIDIA and Valve

Maryland firms score $5M to manufacture everything from soup to nanofiber

This Week in Jobs: Add these 26 tech career opportunities to your vision board