In the future, will all of our vegetables be grown on stacked shelves in temperature-controlled rooms lit by LED lamps? As climate change slowly disrupts the natural rhythms of the growing cycle and if housing demand in exurbia continues apace, will farms just move inside? Honestly, maybe. With a look at the state of the indoor farming industry as it stands today is Brooklyn startup Agrilyst’s State of Indoor Farming 2017 report.

Agrilyst, which we named the No. 4 startup in the Brooklyn tech world last year, builds data analytics software for farmers to more efficiently manage their crops. As such, their report, which surveyed more than 150 growers was data- and graphic-rich.

“I think the most interesting thing is we had a lot more data on indoor vertical farms than we did last year as separate from greenhouses,” Agrilyst founder Allison Kopf said by phone last week. “There are a lot of macro factors [for why that is]. There’s a lot of attention right now in vertical farming. Produce buyers are paying attention, you’ve got the cannabis industry, which has taken off in the last few years, and so you’ve got these things going on in the industry where entrepreneurs are excited to build these things.”

You can read the whole report here, but below are some of the facts that made us lift our eyebrows:

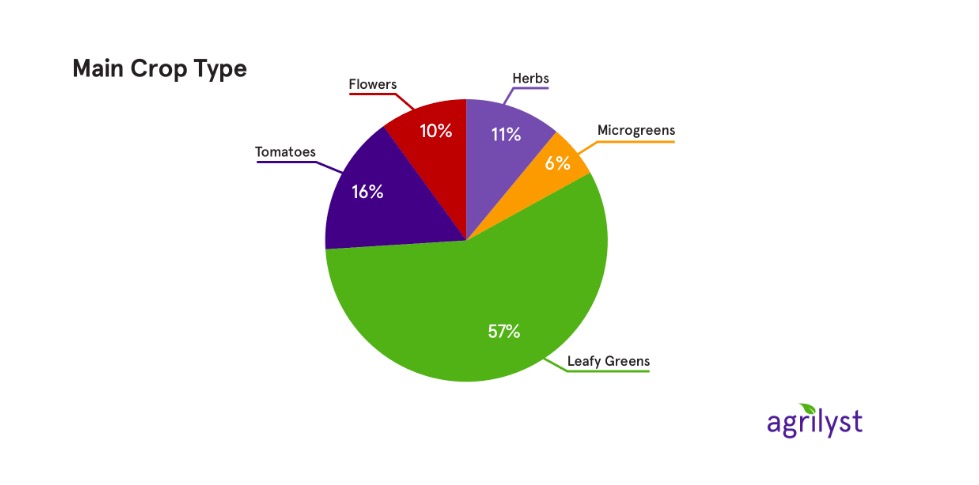

Read the full report- The five main crops grown were: leafy greens, microgreens, herbs, flowers, and tomatoes, with more than half of respondents growing leafy greens.

- Due to decreases in technology costs (LEDs in particular) and an increase in local demand for food, we’re seeing an increase in alternate growing systems, particularly fully enclosed vertical systems.

- Farmers have to grow crops that are high revenue generating. To do this, you can grow crops that are specialty items, like flowers, or you can target crops that have quick growth cycles, like leafy greens. If you think about a vertical growing system, you want to grow crops that are physically short (so you can get many layers), that have short growth cycles (so you can turn your facility over many times), and are highly perishable (more valuable when grown locally).

- The average yield of conventionally grown tomatoes in 2016 was 805 cwt per acre, or 1.85 pounds per square foot, according to USDA data. Greenhouse hydroponic tomato growers on the other hand, reported an average yield of 10.59 pounds per square foot.

- Similarly, the average yield of conventionally grown head, leaf, and romaine lettuce is 0.69 pounds per square foot, compared with 8.71 pounds per square foot for leafy greens grown hydroponically in a greenhouse.

- Only 51% of respondents reported operating profitably.

- 100% of flower operations reported profitability, along with 67% of tomato growers, and 60% of microgreens growers.

- Herbs and leafy greens were the least profitable crops.

- For large vertical farms, energy made up about 25% of total operating expenses at around $8 per square foot. For small farms, energy cost $3.45 per square foot, or about 12% of the operating expenses.

- Indoor vertical farms needing many more employees than greenhouses. This makes automation technologies incredibly important as the industry matures.

- Large farms pay employees double what small farms pay per hour.

- While LEDs are one of the things growers are most excited about, it also came in second on the list of things growers think are over-hyped.

Before you go...

Please consider supporting Technical.ly to keep our independent journalism strong. Unlike most business-focused media outlets, we don’t have a paywall. Instead, we count on your personal and organizational support.

Join our growing Slack community

Join 5,000 tech professionals and entrepreneurs in our community Slack today!