Apkudo, the Baltimore-based company focused on supply chain automation for connected devices, landed $14.4 million in growth financing to expand its customer base globally.

This funding round is a continuation of the Series B where Apkudo raised a nearly identical $14 million in November 2020. This round was led by Closed Loop Partners’ Leadership Fund and included venture capital firms such as Birmingham, Alabama-based Harbert Growth Partners and Philadelphia-based MissionOG. The round also saw participation from existing investors based in the DC-Maryland-Virginia region: Grotech Ventures, which has an office in Hunt Valley, Maryland, and McLean, Virginia-based Lavrock Ventures.

“We’re that type of company that you come to and you’re like, ‘I got a real big tough problem that I don’t think is solvable,'” Darwin Stephenson, Apkudo’s chief innovation officer, told Technical.ly. “We’ll turn that around really quickly.”

Josh Matthews and Ben Leslie founded Apkudo in 2011. Through the company, they developed a platform, called Hive, to manage and optimize the supply chain for any device with connectivity to a broader network or the internet. It has grown with a focus on smartphones, but the platform can also manage connected devices such as wearables, TVs or others used in the home — pretty much anything connected to the internet of things

Two years ago, the company was working with names like AT&T, T-Mobile, Verizon, Samsung, Amazon and FedEx Supply Chain Services to analyze the history of connected devices and available software. This evaluation helped provide insights for how Apkudo will be used going forward on a second or third life cycle. Apkudo has expanded to working with laptops and computers and has a partnership with Dell to signify that growth and market expansion. This new funding aims to amplify those efforts.

Darwin Stephenson. (Courtesy photo)

CEO Matthews previously told Technical.ly that Apkudo’s technology answers the question, “What do I do with this device right now?” for mobile phone carriers, device manufacturers, third party logistics providers, wholesalers and traders.

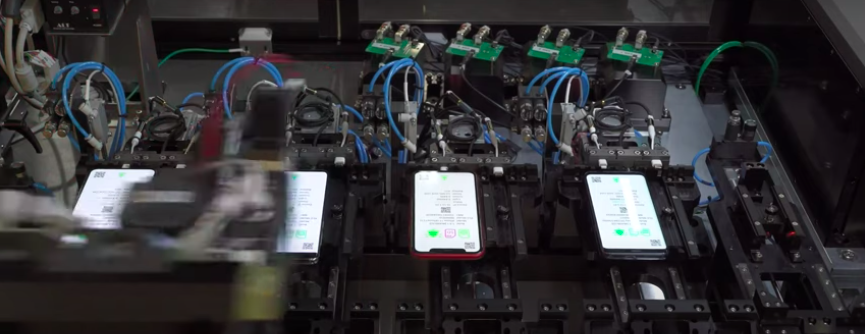

Stephenson noted that while the company’s headquarters will forever remain in Baltimore, most of its 100 employees are now remote. The quarter of its staff who do work on site are affiliated with the robotics line at Apkudo’s facilities in Texas’ Dallas-Fort Worth area. Where those facilities pop up is dictated by the logistics of shipping and device manufacturing for the phones, laptops and other devices Apkudo assesses and certifies on functionality and cosmetics.

The Baltimore headquarters “will remain our anchor,” Stephenson said. “But, as we expand, it’s really about where these devices go.”

Apkudo intends to open a facility similar to the Dallas-Fort Worth location in Europe. Stateside, the company looks to hire engineers as it begins partnering with companies in the electronic-waste recycling field and working on devices like satellites. Branching out into these new industries creates new engineering questions that the company needs to solve.

“Part of that engineering challenge is not just what we know today, but getting out to the full life cycle of these devices,” Stephenson said. “How can technology make some of those old processes better, and faster? It’s a natural extension of the platform, but it’s a physical extension. That means we’re getting into robotics, which is completely different from what we do today, which is largely cleaning, cosmetic grading and functionality testing.”

Donte Kirby is a 2020-2022 corps member for Report for America, an initiative of The Groundtruth Project that pairs young journalists with local newsrooms. This position is supported by the Robert W. Deutsch Foundation.Join our growing Slack community

Join 5,000 tech professionals and entrepreneurs in our community Slack today!

Donate to the Journalism Fund

Your support powers our independent journalism. Unlike most business-media outlets, we don’t have a paywall. Instead, we count on your personal and organizational contributions.

The tax change that blindsided tech firms may finally be reversed — but time is running out

How to win on Shark Tank: Tips from an entrepreneur who scored a deal

She used to build code, alone. Now she builds ecosystems, hand-in-hand with communities.