In the tech sector, trends change, social media platforms can lose their popularity, and cryptocurrency has not (yet) replaced regular money the way some were hoping. Yet what doesn’t change is that products need to be made to meet consumer demand.

2020 reminded the world how fragile the global supply chain can be, and since then, manufacturers and economics pros have been trying to change where those products get made. It’s the reason why Congress approved the bipartisan CHIPS and Science Act in 2022 — a $280 billion legislation that committed to providing $52 billion in subsidies for US semiconductor manufacturers, as well as funded the EDA Tech Hubs program.

In Pittsburgh, it also partly inspired the launch of the Robotics Startup Factory, with an aim to offer local companies physical space, guidance, and the opportunity to perform rapid prototyping and harness small-scale production onsite.

“We’re going to create companies that are developing products that can be produced in Western Pennsylvania — not just produced in China, and not just produced somewhere else,” Mike Formica, AlphaLab Gear’s former managing director of hardware, told Technical.ly in 2022.

But a company needs manufacturers to make its products. Manufacturing jobs have been declining in the states for years, and some employers are still downsizing, Catalyst Connection Workforce Initiatives Director Scott Dietz said — but even so, manufacturers are high in demand.

Manufacturing-focused nonprofit Catalyst Connection has made a name for itself throughout Southwestern Pennsylvania through technology training and consulting services. Typically, that entails helping the small businesses it’s serving understand and envision how they can incorporate technologies such as robotics, cybersecurity, artificial intelligence and machine learning into their manufacturing processes.

“We work with about 2,800 manufacturing companies across 12 counties,” Dietz said during Pittsburgh Robotics Network’s 2023 Discovery Day showcase last week, “and every one of those companies we talked to is hiring. So if you ask me, the manufacturing companies that are here today, they can pretty much guarantee every single one of those looking for high-quality talent.”

Catalyst Connection Workforce Initiatives Director Scott Dietz. (Technical.ly/Atiya Irvin-Mitchell)

Dietz added that within the manufacturing field, occupations such as machinists and welders and skills such as industrial maintenance and engineering are particularly in demand. If a person was looking to pivot careers — if they were willing to learn — they could have a promising career in the sector, he said.

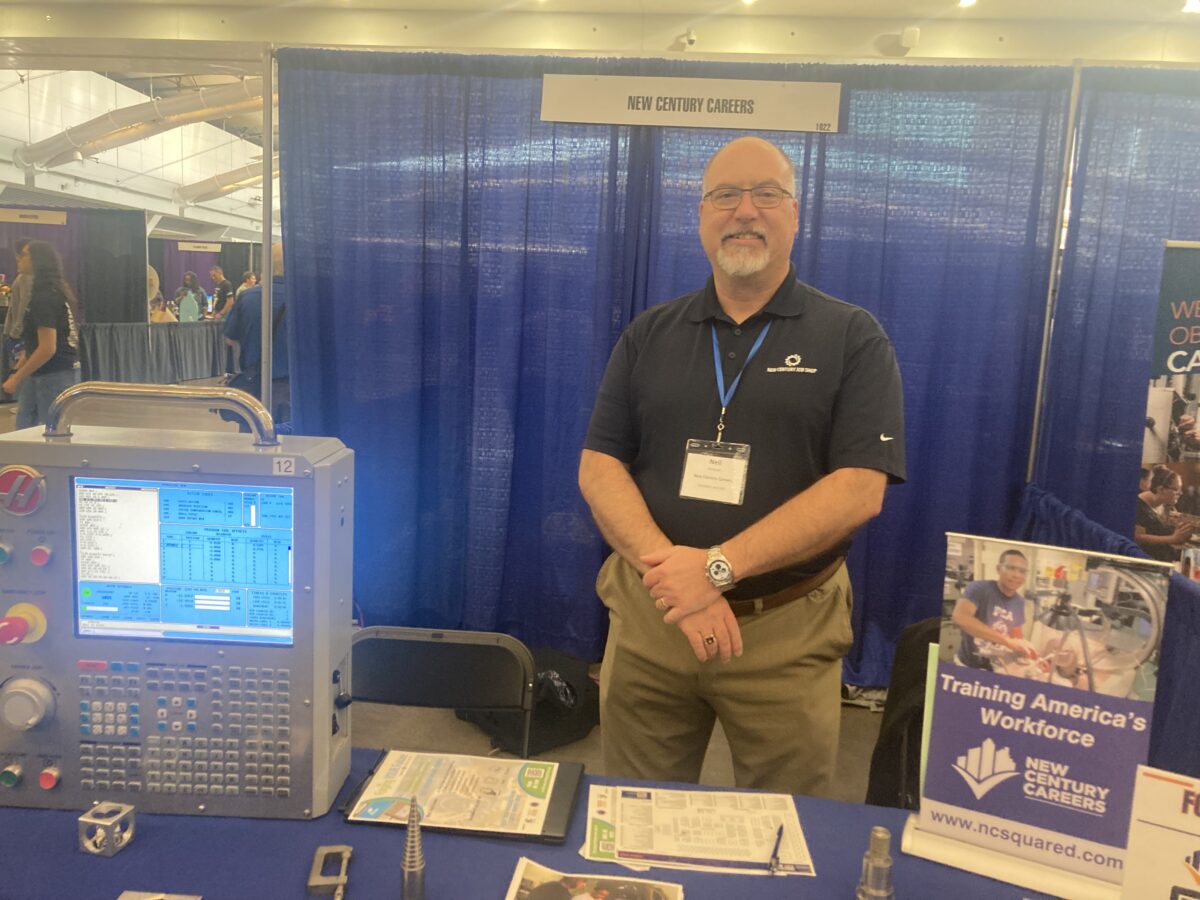

New Century Careers President and CEO Neil Ashbaugh agreed. His org is a nonprofit dedicated to training machinists. In addition to supply and demand, as more Baby Boomers retire, more manufacturers will be needed to fill their positions. Machinists, he said, serve a necessary and versatile role in the manufacturing sector because they assist engineers and often have to have the skills engineers possess to do their jobs effectively.

“Whether it’d be for robotics or 3D additive printing, a machinist is the person that’s going to build a lot of the key components of the robot or of the 3D machine,” Ashbaugh said. “Machinists are also then able to learn the technologies to operate with the robotics and the automation systems and the 3D printers.”

While these past few years have shown us that even the most seemingly secure of industries can be riddled with uncertainty, Abshbaugh said the reason that he thinks manufacturers will continue being in demand is that even when times are hard, things need to be made.

“Everything needs to be created. Everything that a common citizen runs into has to have something that’s manufactured. Everything that you have has a blueprint, and machinists are always involved with that,” Ashbaugh said. “So for everything that’s created, for everything that we consume … somebody had to manufacture [it].”

Atiya Irvin-Mitchell is a 2022-2024 corps member for Report for America, an initiative of The Groundtruth Project that pairs young journalists with local newsrooms. This position is supported by the Heinz Endowments.

This editorial article is a part of Resilient Tech Careers Month of Technical.ly’s editorial calendar.

Before you go...

Please consider supporting Technical.ly to keep our independent journalism strong. Unlike most business-focused media outlets, we don’t have a paywall. Instead, we count on your personal and organizational support.

Join our growing Slack community

Join 5,000 tech professionals and entrepreneurs in our community Slack today!

The person charged in the UnitedHealthcare CEO shooting had a ton of tech connections

From rejection to innovation: How I built a tool to beat AI hiring algorithms at their own game

Where are the country’s most vibrant tech and startup communities?