When Delaware went into lockdown in March amid coronavirus’ surge, makerspace NextFab in Wilmington’s Creative District sat as empty as so many restaurants, libraries and offices.

Creative people can work anywhere, in theory, but if your medium is laser-cut acrylic or intricately machined wood, you need access to that technology. NextFab’s big draw is that it offers that access, including to the wood shop’s Shopbot robotic machining tool, laser cutting and large-scale 3D printing. You know, things the average maker just can’t do at home.

While NextFab pivoted some of its workshops into webinars to keep members connected during the lockdown, it’s been reopened on a members-only basis since June 11, with a requirement that everyone wears a mask and safety glasses and follows room capacity guidelines — an extra bonus for makers who like having time in the shop by themselves.

We wanted to find out what NextFab Wilmington makers were up to as we wrap up Design Month. A handful hopped on a Zoom call with Technical.ly, where we chatted with a variety of creators who are getting back into the groove of things at the makerspace.

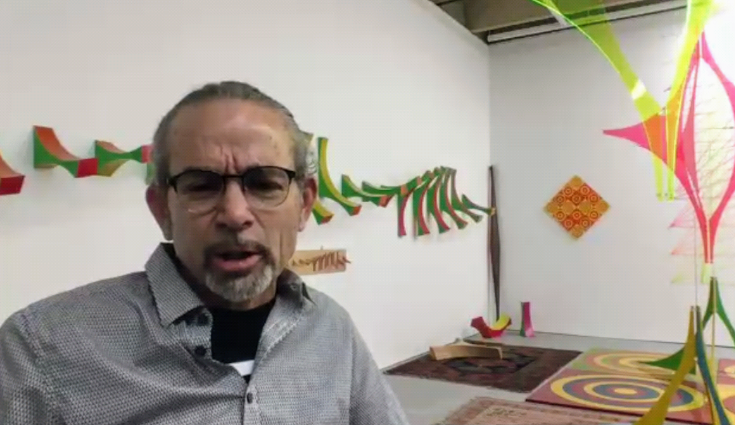

The sculptor

Dennis Beach is a well-known fine artist in the region — in 2018, he created two large sculptures for the new Comcast building in Philly — and he even has his own makerspace. But NextFab’s high-tech equipment like the Shopbot and laser (both used for the Comcast project) keeps him experimenting with maker tech.

https://www.instagram.com/p/B0rijf3lsXl/?utm_source=ig_web_copy_link

Beach does a lot of work with wood and acrylic, which can be laser cut into dynamic shapes that have the added dimension of projecting colors with light.

The entrepreneur

Yemina Israel is the founder of Addi Naturals, a natural hair and skin care line she makes by hand using plant ingredients she grows herself. She uses NextFab to create the display and branding pieces she uses at craft and trade shows, as well as for photographing her products for social media.

https://www.instagram.com/p/Bs3uaYzHZyC/?utm_source=ig_web_copy_link

“I’m a tiny company, but it allows me to create professional branding that looks like I’m a big company,” she said. Access to NextFab’s facilities has also encouraged her to try mediums she may never have thought to try before, such as wood. Her next project, she says, is a display piece made in the wood shop.

The product designer

Chuck Dobbs, architect for Tetra Tech Architects, creates unique pieces using the wood shop and Shopbot. Pieces like his “Buddy Bench” recontextualize objects (in this case, surfboards) as functional furniture that looks like art.

https://www.instagram.com/p/CB8ZZSAlnO3/?utm_source=ig_web_copy_link

The lockdown made it challenging for Dobbs to work on new projects. Now that the makerspace is open again, he’s starting work on a bed frame; we’ll be keeping our eyes on Instagram to see how it turns out.

The eclectic

Linda Celestian is an artist and educator who creates all kinds of art objects, from large fine art pieces to jewelry — and she gets a lot of ideas based on the machines she has access to at the makerspace, including the laser cutters.

https://www.instagram.com/p/B5WDnaiF0Hu/?utm_source=ig_web_copy_link

“You can sort of ‘mass produce’ pieces that still feel one-of-a-kind,” she said, showing creations that include laser-cut plexiglas earrings and a frame laser engraved with a pattern taken from real lace. She sells many of her creations online.

The woodworker

You can’t order a custom butcher block from Sam Kawalek yet, but after building one for a friend’s butcher shop in Richmond, he’s working on making butcher blocks as a contract business.

Sam Kawalek. (Courtesy photo)

“There will be a website,” he said, where people can order custom blocks and purchase smaller butcher block cutting boards — all stamped with Kawalek’s trademark Koala, a play on his surname.

This editorial article is a part of Design Month of Technical.ly's editorial calendar.

Before you go...

Please consider supporting Technical.ly to keep our independent journalism strong. Unlike most business-focused media outlets, we don’t have a paywall. Instead, we count on your personal and organizational support.

Join our growing Slack community

Join 5,000 tech professionals and entrepreneurs in our community Slack today!

The person charged in the UnitedHealthcare CEO shooting had a ton of tech connections

Delaware students take a field trip to China using their tablets and ChatGPT

From rejection to innovation: How I built a tool to beat AI hiring algorithms at their own game