I was working at the University of Delaware in the late 2000s. I lived outside of Newark when Chrysler shut down its assembly plant and fired all 2,100 of its employees. Word of the closure started to spread in February of 2007 — almost ten years ago to the day.

I remember in 2009 when the university officially acquired Chrysler’s massive 272 acres of land along Route 896. The acquisition was billed by former President Patrick Harker as historic. The classrooms and labs “will occupy this site and serve as catalysts for economic development and incubators for discovery,” he said at the time.

In hindsight, that bit about “incubators for discovery” seems nearly prophetic.

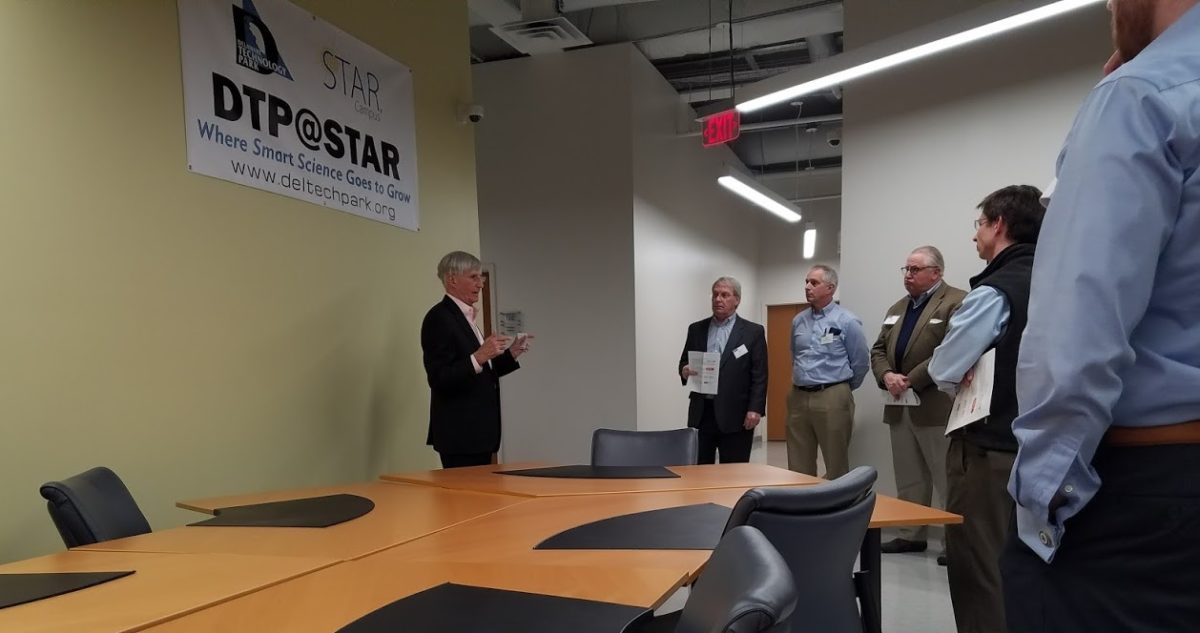

I was on hand this week as the Tech Forum of Delaware worked with the Delaware Technology Park (DTP) to provide a tour of the new STAR (Science, Technology and Advanced Research) Campus incubator, DTP@STAR. The ribbon cutting went down in October of last year, and companies began filling the labs and offices and getting to work immediately.

The tour of the space started with an introduction from Mike Bowman, president of the DTP and associate director of the Office of Economic Innovation and Partnerships at UD. “Imagine about 10 years ago,” he told us, “standing here where we’re standing on over 272-acres of automotive assembly. That was Chrysler. Fast forward to now, and the only remaining building, or piece of a building, is this building.”

Bowman pointed up, explaining that the high ceilings were a part of the massive assembly bay in the Chrysler plant. Those high ceilings were once home to the birth of automobiles. Now they’re home to the birth of innovative companies, ideas and products.

The DTP@STAR campus is split. The University’s College of Health Sciences sits on one side of the facility, while DTP’s commercial space sits on the other. It’s essentially a coworking space for science and IT companies. The STAR campus will soon be home to a 10-story tower, and the College of Health Sciences will move out of DTP’s building and into six of those stories. DTP will take over the remaining space, making room for even more companies. DTP rents the space to companies, and the tenants have access to equipment, labs and offices.

For now, DTP@STAR is home to more than 12 companies working in fields that range from life science to material science and IT. The space is even home to Spin-In, a concept Bowman seemed pleased to host that lets companies hire teams of students to work on and build a new idea for a year. The students get hands-on, experiential learning while the companies, potentially, get a working idea to take to market.

As Bowman finished his introduction and took us back to the wet labs and office spaces behind closed doors, the passion and excitement for Spin-In seemed to spill over to just about every single tenant working in the DTP@STAR Incubator.

Bowman is seemingly unique in this regard. As he took us past each lab, sometimes breaking his own rule and opening doors to show us workspaces, he was excited by every company. He called them out by name, spilled a little information about their background, and told us what they were working on.

He told us that he was excited about them, and excited to see them achieve. “We want to grow ’em up and move ’em out,” he offered.

One particular company that Bowman was excited by, and one that I’ve heard mentioned in passing by other science entrepreneurs here in Delaware, is STF Technologies, an astronaut gear company with clients that include NASA, the U.S. Army and the National Science Foundation. Right now, Bowman said, the company is working on developing products that react to potentially penetrating impacts by stiffening into a sort of armor.

Bowman also spoke about plans for a train station that would connect the STAR campus to other areas in a region. As he mentioned the future of the incubator itself, he talked about how deliberate DTP has been about selecting the companies that come in. He wants to take the right steps, and it seems that he’s doing it the right way.

DTP@STAR has only been open officially since October, but it’s already filled with companies working on potentially industry-disrupting ideas. And it’s all happening at the site of an old automobile plant that, at its peak, employed more than 5,000 people.