Greg Simmons stood in the center of a room, surrounded by 90 cameras. The lights were low for a moment. Then, a flash of light. With that, the UMBC Vice President for Institutional Advancement was on his way to becoming a 3D model.

As UMBC President Freeman Hrabowski later showed as he cut the ribbon on the system, there can also be multiple flashes to capture movement.

Going forward, administrators won’t be the only ones stepping into the center of the ring. The technology has been used by Hollywood, but the college envisions using it to help create video games, or build prosthetics. Then, there’s objects. Think works of art, historic artifacts, or transplants for trees.

“Being able to capture a 3D model is just a priceless ability,” said Marc Olano, a professor of computer science and electrical engineering who helped lead the effort to bring the scanner to UMBC. Olano also teaches video game design.

After UMBC received funding through a grant from the National Science Foundation, the scanner was custom-made in the lab at Direct Dimensions’ Owing Mills headquarters over the last year, then transported to UMBC’s campus. Over the summer, two interns from UMBC helped with the project.

The photogrammetry camera rig simultaneously takes pictures around the person or object. “That flash is the first step,” Olano said. Then, software combines the images into a 3D model. Overall, the processing involves four major steps. An initial 3D model takes 30 minutes to “a few hours,” while a higher resolution model could take as much as a day.

Direct Dimensons has a longstanding presence in Maryland, and company president Michael Raphael said industries like defense, apparel and healthcare have an interest in the technology. With university researchers now interested as well, he believes the scanner could play a role in making Maryland a national “center of excellence” specifically for scanning.

“My goal is to lure a national manufacturing institute dedicated to 3D scanning to Maryland,” Raphael said.

At UMBC, the scanner also plays into broader programming aimed at using digital media. The university is also adding technology to help work with the model once it is created.

Next year, the university is planning to add an immersive virtual reality environment. Known around the ITE building as “the cave,” it’s a 15-by-20-foot room that doesn’t require goggles (but could for augmented reality). We wrote about it more extensively earlier this fall.

The scanner could be a “front end” for the cave, where the 3D models could be examined or manipulated, said UMBC Director of Research Karl Steiner.

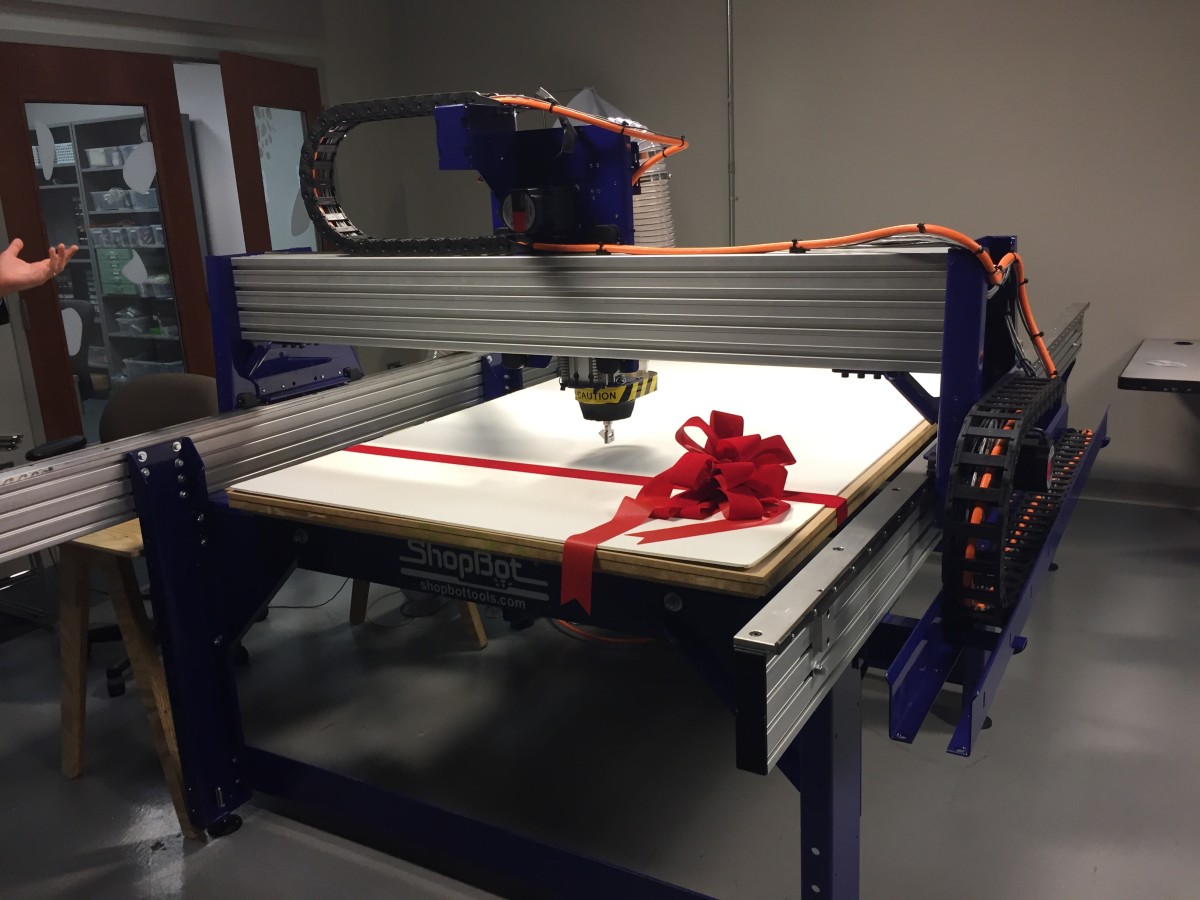

Fear not, there is also the option to bring it back from the digital beyond. Just down the hall, the university recently purchased a CNC router.

“We got the 4-by-8 because we will never be in want,” said Lisa Moren, who runs the graduate program of intermedia and digital arts.

The router doesn’t need to cut in straight lines. Among other uses, that makes it especially enticing for elements of an art piece that would normally require multiple pieces fastened together. The university has about a dozen fabrication facilities, but the new addition is the biggest.

“There isn’t one like it on campus,” Moren said.

It also cuts its own ceremonial ribbon.