David Jones and Michael Armani were both looking at low-cost automation for their own projects. It turned out they found their way into low-cost 3D printing.

“I was doing it for robotic harvesting, because there are some crops you can’t harvest technically, they’re too easily damaged,” Jones said. “Robotic harvesting is slow and tedious and expensive, so if you’re going to do it that way, you’ve got to do it affordably.”

When the two got together, something totally different emerged.

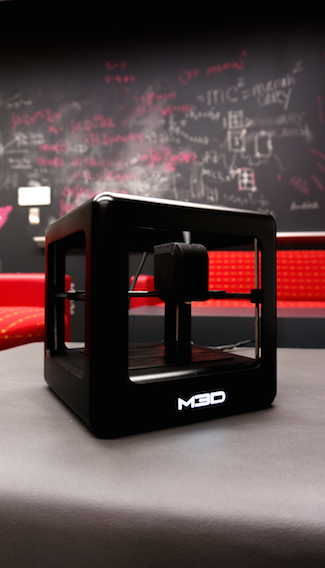

Now, Fulton-based M3D’s Micro 3D printer, which raised more than $3.4 million on Kickstarter earlier this year (the most ever for a 3D printer), will ship in the next month or two.

“I like to call it an epic marathon,” Jones said. “We’re between the stage of beta and production units so we’re working out all of the kinks in production and software and everything at the same time. Around December, everything should be nice and ready for a clean consumer product.”

What separates M3D from other printers on the market is the price and ease of assembly. Other 3D printers may cost several times as much and are often arduous to assemble. The M3D costs $349 to preorder (some Kickstarter backers got it for just $200) and comes ready to go out of the box. Even Jones, with a background in computer science, says he had trouble.

“When Mike and I first started getting into 3D printers we actually tried to build one of our own and him being an engineer with a Ph.D., it took both of us about four days to put one together and get it working properly,” he said. “So it’s not something your average consumer can do and do well.”

The cubic M3D carries a small footprint and is about as tall as a few college textbooks stacked atop another. The printer also can use special color-changing filaments. Jones said this could have applications for items like mugs (so you can tell if your coffee is hot) and pet cages (to tell at a glance if your furry friend is comfortable).

“There is a compound that’s mixed into the plastic that changes the chemical properties when the temperature changes,” Jones said.

As Jones, Armani and their employees rush to build the preordered printers, they’re also doing so from a new home in Fulton. The company was lured from Bethesda by Howard County’s growing emphasis on additive manufacturing.

“We wanted to be a bigger part of this trend in Howard County that’s going on with 3D Maryland,” Jones said. “The state has been very supportive of our efforts to create jobs and bring jobs back to the US. Fulton’s a real nice area, very safe and up and coming.”

M3D is almost ready to ship its record-breaking 3D printer