Growing up, Ellie Weinstein didn’t necessarily see herself getting into the restaurant, confections or chocolatier world — her passion was engineering.

But a high school hobby project exploring 3D printing has pulled her in that direction. When she took an intro to engineering class at Chestnut Hill Academy, her teacher prompted the students to try working with materials other than plastic, and chocolate seemed like an interesting option.

“Honestly, I stumbled into it a little bit,” Weinstein said.

The project stuck. Weinstein worked on the 3D printer while she studied mechanical engineering at the University of Pennsylvania. She’d built the machine and had other students working with her as her senior design capstone project. When she graduated in 2019, Weinstein took what’s now known as Cocoa Press full time, completing the Pennovation Center’s six-week accelerator program.

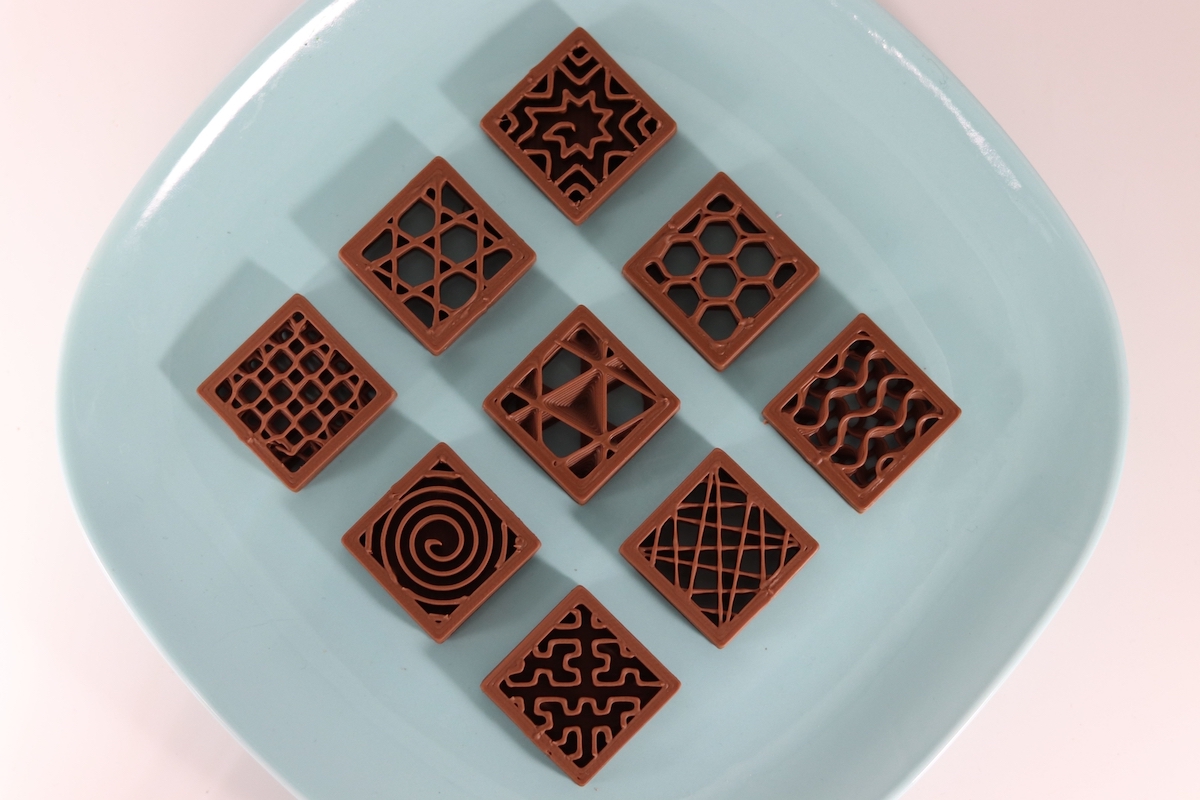

Since then, Weinstein has been selling machines that can custom print anything made of chocolate. It calls for a lot more temperature control than traditional 3D plastics, but the founder saw a niche for specialized confections. Weinstein herself created chocolates for events like weddings, and when Penn president Amy Gutman left her post in 2022.

Weinstein also found a place within the maker community, attending fairs in New York and Philadelphia, and local meetups. At these events, hobbyists and confectionery shop owners would ask how the Cocoa Press could allow them to make custom chocolates and how the price could compare to getting specialized molds made.

“With 3D printing, of course, you know, complexity is free if you already have the design which you need for the molds, anyway, you can just print it and have it same day,” Weinstein said.

Selling commercial-sized machines to these customers was the main business plan for the last few years, but Weinstein is currently launching a pre-order for the company’s new focus: At-home, DIY chocolate printing machines. Instead of the larger machines, which cost about $10,000, these at-home machines will cost about $1,500. Each machine comes with a DIY kit that will take about 10 hours of assembly, food safe materials and chocolate for printing. Users don’t need prior experience with chocolate, Weinstein said, nor a ton of experience with 3D printing.

“I think just the understanding that it’s a little bit messier than plastic sometimes, and in terms of 3D printing, I think as long as people are willing to really put in the time, they don’t necessarily need experience with 3D printing just that understanding that it’s not going to be plug and play,” Weinstein said.

The founder said she expects machines to ship this fall to the US and Canada with more regular rollout by Valentine’s Day. Though Weinstein didn’t necessarily see her engineering career taking her this route, she sees major potential for the technology to impact the future of food.

“I think just food printing in general is going to become a bigger part of what companies are using, whether that’s decorating on cakes or just for like, wedding cake toppers, whatever it might be, eventually in in space or fake meat printing,” she said. “All the technology is actually fairly similar. So I think long term, I see chocolate printing as the start and the easiest way to introduce food printing to the market.”