If you’ve always wanted your very own 3D printer, but were hesitant to shell out the cash, maybe you’d rather pay to make one yourself.

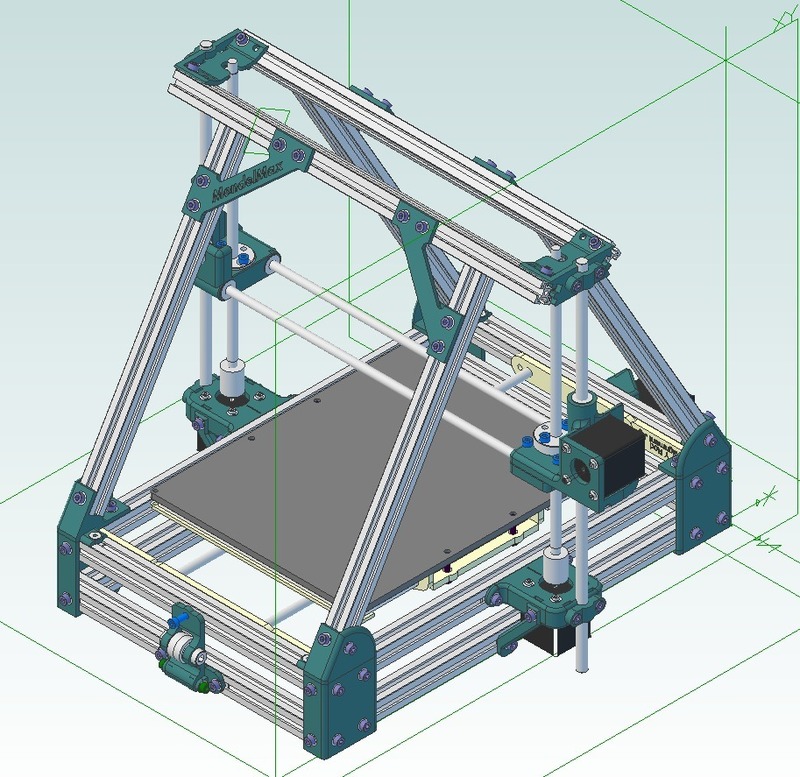

For roughly the same $2,000 price tag as a retail version of the MendelMax 3D printer or just a bit more than buying your own kit and trying at home, NextFab Studios will to help you build your own and provide you with the 3D modeling software license you need to get printing, even if you just want to print another printer. That’s right the printer can supposedly self-replicate (we’ve never seen this happen so we can’t confirm).

“It’s not something you can do on your own without any knowledge or experience,” NextFab’s Community Service Specialist Itsuki Ogihara said. “You need to know some tricks.”

The 3D prototyping community workspace currently located at 37th and Market in the University City Science Center will be hosting the two-day, seven-person “Build-Your-Own 3D Printer” workshops three times throughout the summer.

To register for a workshop click here.

There’s a certain element of sticker shock to a $2,000 registration fee, but those in the NextFab community may eventually get used to it.

Ogihara says that NextFab currently derives no revenue from running these types of big ticket workshops (due to the cost of materials), but that is likely to change once the studio expands to its new space at 20th and Washington, which is currently under construction.

“We’ve been doing this more as a community service and PR,” Ogihara said, referring to events like the Build-Your-Own 3D printer workshop. “But in new space, we are going to have much bigger classrooms, where we can hold substantial workshops. There, we intend to bring in revenue through them.”

NextFab’s model of using classes and workshops to reach out to the community and attract more members is not unique. TechShop, a similar membership-based workshop in Menlo Park, CA, also holds classes and events, but Ogihara says they don’t have full time staff. NextFab has 16 full time staff members.

At the moment, the studio derives half of its revenue from memberships — they have 160 full-timers — and half from contract work it does for clients seeking custom fabrication, Ogihara told Technically Philly.

We’ll have to wait until the new space is up and running to see how more space, membership, and programming interact to fuel their bottom line.

To find out more about building your own 3D printer click here, or get glimpse of what to expect by watching the time-lapse video of a MendelMax being built:

And a quick video of a finished printer starting a job:

Join the conversation!

Find news, events, jobs and people who share your interests on Technical.ly's open community Slack

Philly daily roundup: Minecraft in a Philly school; PTW kicks off; Tech and art happy hour

Philly daily roundup: Philly's top innovation leaders; City buildings go solar; PTW kicks off on Friday

Philly daily roundup: UPenn's AI master's degree; Advice for EDA Tech Hubs; Last day of ACP