Heavier than a 737 jet. Longer than six sedans. Taller than a two-story building.

The towering Dreadnoughtus schrani, discovered in Argentina by Drexel University’s Dr. Ken Lacovara (who now works for Rowan University) and detailed in a 2014 publication in Scientific Reports, is one of the largest dinosaurs ever found.

In spite of its massive proportions, this Titanosaur is making a comeback in Drexel’s Laboratory for Biological Systems Analysis with the help of 3D printers, servomotors and the cooperation of two bright students: Kristyn Voegele, from the doctorate program, and David McDevitt, an engineering undergrad.

Set on a quest to study the animal’s motion the way it once was, Voegele provided McDevitt with her ample knowledge of the fossil, as she was part of Dr. Lacovara’s research team. “Looking closely at the fossil, there are textured areas where muscle was attached to the bone. We call that a muscle scar,” she explained.

Because the dinosaur’s bone structure was 70 percent complete and very well-kept for its age, there are plenty of available muscle scars, which can pinpoint where a muscle was attached to bone. By checking these connections against the skeletal system of alligators and birds — dinosaur’s closest relatives — researchers can say with higher certainty how the dinosaur’s joints moved.

This study is part of Voegele’s doctoral dissertation, which focuses on studying the movement of the extremities. That’s where McDevitt’s engineering chops came in. “I wanted to develop a testing apparatus so that Karyn could develop all her different hypothesis as to the motion of the limbs,” he said.

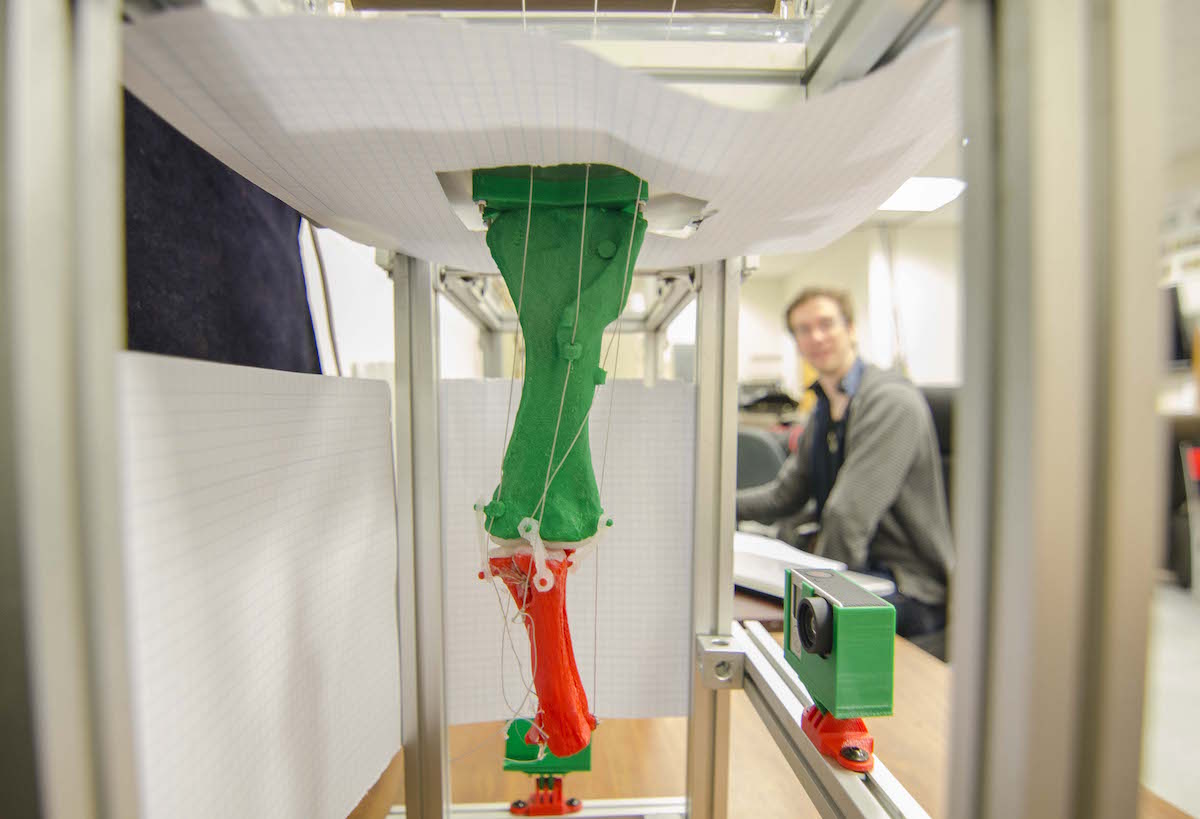

The resulting device is a metal structure with a motor bed capable of moving up to eight antagonistic muscle groups — represented with thin metal coil — through a set of servomotors. When one muscle or ligament “flexes,” the other “relaxes.” It was developed with the express purpose of being as easily modified as possible. In fact, the rig can sustain up to six motor beds for a total of 48 antagonistic muscles.

“Any kind of limb structure can be represented thanks to the rig,” McDevitt said as he sprung the machine into action on a recent visit. In doing so, McDevitt recreated a motion that had not seen the light of day since the Upper Cretaceous period (roughly 75 million years ago).

At the touch of a button, the machine makes the 3D-printed humerus and radius replica move back and forth in perfect harmony. “We haven’t studied dinosaurs in this way before,” said McDevitt. “We used to rope the physical bones up to the ceiling and then figure out the movement patterns from there. This sort of application of engineering techniques allows for a higher precision than ever before.”

https://youtu.be/HPVr7_Tg_bU

In fact, the 3D printer has been a great stride forward for this kind of research, allowing scientists to replicate complex structures at any desired scale quickly and inexpensively. Each replica of fossils, depending on the scale, can take between nine and 14 hours to be completed.

The research duo is currently focused on studying Dreadnoughtus’ elbow. In Voegele’s opinion, the goal going forward is to produce a fairly robust model that shows the way this magnificent creature roamed the Earth. However, another interesting result has come of the research process: the value of collaboration between science fields.

“We truly could not have done this without the knowledge of each other,” she said.