A steel frame moves from workstation to workstation, first being outfitted with wall panels, then threaded with electrical wiring and plumbing, and finally mounted to a steel chassis to form one wall of a bathroom “pod.” This pod will then be slotted into a larger module comprising a bedroom and kitchen, and the full module will be stacked atop similar modules, forming a multi-level apartment building.

This is what work is like inside Full Stack Modular, a 100,000-square-foot factory in the Brooklyn Navy Yard that builds modular housing — a form of construction where a structure is built in pieces (or modules) in a factory and then assembled at the construction site (also known as prefabricated housing).

“It’s pretty much Legos and Erector Sets,” said CEO Roger Krulak, who founded Full Stack Modular in 2016. “It’s simpler and more effective than what we have now.”

Krulak is a 35-year veteran of the building industry who launched Full Stack under the belief that the current system of construction is broken. Among the issues, Krulak says, is that architects, developers and contractors all have competing interests, which leads to projects going over budget and being completed late.

His solution? Make the construction process resemble manufacturing.

“Pretty much everything in the world people use on a regular basis is manufactured, except buildings,” said Krulak. “We are just trying to steer this industry towards progress.”

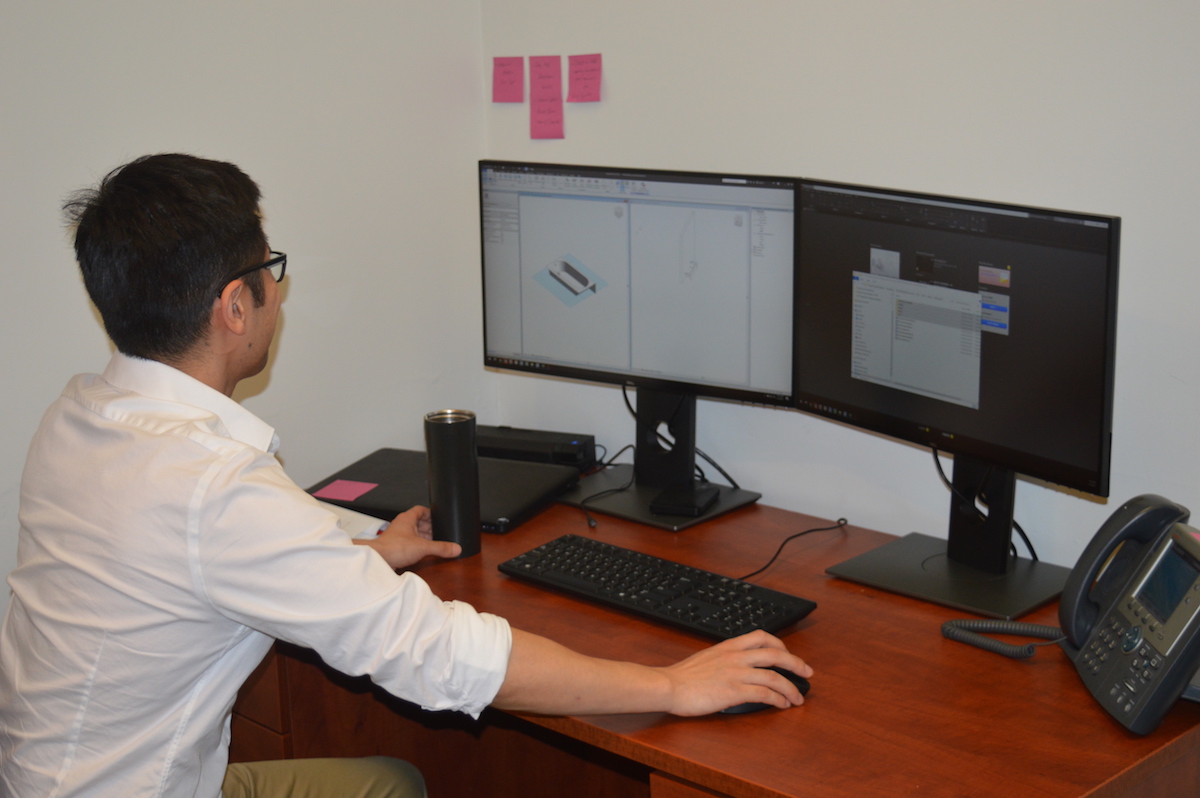

Full Stack Modular approaches the construction of a building by creating an electronic production model of what is going to be built and all of the instructions on how to do it. Some processes can be automated while others require skilled workers. They then create an assembly line organized by efficiency, and use a team of trade associates to build the modules. Krulak says this process is safer, less wasteful and guarantees time and cost predictability.

Advancements in technology have made this type of construction possible. Full Stack uses 3D modeling and a process known as metrology to assure they are building their structures to spec. Metrology, or the science of measurement, can be used to determine how something built in the factory will fit when it is arranged on-site.

“When you are constructing a 30-story building, the dimensional tolerances go way down because if your measurements are off you end up with the Leaning Tower of Pisa,” explained Krulak. “With metrology, you can see if the module is going to fit the way it is supposed to.”

Krulak purchased Full Stack’s technology along with the factory that houses it from his former employer, real estate developer Forest City Ratner, in 2016. While still with Forest City Ratner, Krulak oversaw the construction of 461 Dean, a 32-story, 363-unit residential building next to Barclays Center that is considered to be the tallest building ever built via modular construction.

Full Stack Modular is working on multiple residential housing projects in Manhattan and Brooklyn. The company is currently raising $12 million in Series B funding after closing a $6 million Series A in August of 2017. Krulak says the money will be used to expand Full Stack’s workforce from 40 to 140, and to improve their tech.

The modular housing industry is expected to grow at an annual rate of 6 percent in the United States, and Krulak’s goal is to stay out in front of the competition as prefabrication gains wider market acceptance. Currently, Full Stack Modular is the only modular housing operation in New York City.

“We are on the bleeding edge,” Krulak said.

With a worldwide housing shortage approaching 1 billion, Krulak believes it is only a matter of time before modular goes mainstream.

“We can’t solve this problem with zero productivity gains,” said Krulak. “It doesn’t work in any other industry, and it’s not going work here.”