Danny Cabrera was a senior at Penn when opportunity knocked.

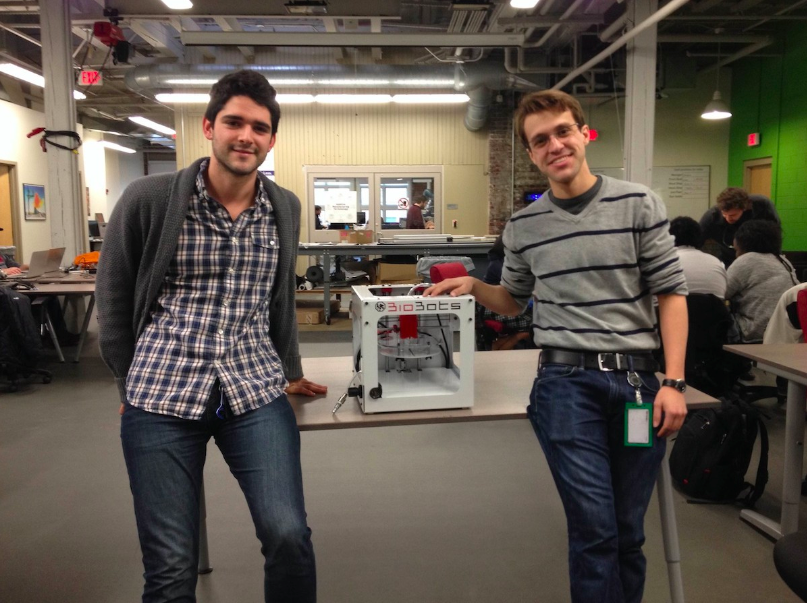

It came in the form of Ricardo Solorzano, a recent Penn bioengineering grad who had done his first two years at Miami Dade College, the same state school that Cabrera had transferred from. They never ran into each other in Florida and first met at Penn a few years later. Solorzano had a prototype for a desktop bioprinter, a 3D printer that uses cells to build living tissue. Did Cabrera want to see it?

And lo, BioBots was born.

Cabrera got swept up in the project and deferred his acceptance to a Ph.D. program in bioengineering at Penn. Solorzano, 25, deferred his acceptance to med school. Then, the pair joined DreamIt Health, a health IT accelerator that invested $50,000 in the startup in exchange for 8 percent equity.

“This was too big of an opportunity to pass up,” said Cabrera, now 22, speaking about forgoing his graduate degree to build the startup.

Solorzano and Cabrera sold 18 BioBots last month, Cabrera said. Academic researchers like Drexel biomedical engineering professor Dr. Kara Spiller, Mount Sinai’s director of cardiovascular cell and tissue engineering Dr. Kevin Costa and Penn bioengineering professor Dr. Dan Huh are using the printers, which use living cells as building blocks.

The researchers area using the BioBots to experiment with printing bone (Spiller), building hearts (Costa) and developing mini stomachs for clinical drug tests (Huh).

BioBots wants to be “the PC of bioprinters,” Cabrera said.

It might sound like science fiction but bioprinters exist. They’re just not exactly user friendly. A traditional bioprinter will run you $250,000, take up a whole room and require a team of people to operate. The BioBot? It’s $5,000, roughly the size of a MakerBot 3D printer and can be run by a single person.

Aside from the DreamIt Health investment, BioBots raised an undisclosed amount from local investors Benjamin Franklin Technology Partners and BioAdvance. The cofounders are still raising money. That’s one reason they’re headed to South by Southwest next month, after being one of 48 startups chosen out of more than 500 that applied to pitch at the conference in Austin, Texas.

BioBots is not a Penn spinout company, Cabrera said, and Penn does not own any part of the startup in the traditional tech transfer sense, though it does have a stake in it through Penn Medicine’s DreamIt Health partnership.

The two founders work out of Washington Avenue makerspace NextFab, where they have a private office and also where they assemble the printers. It takes about four hours to assemble one BioBot, Cabrera said. The frames are manufactured near Center City, while all the plastic parts are 3D-printed. They’re currently building the second generation BioBot.

The BioBot is similar to a 3D printer but instead of using plastic, it uses cells and biocompatible material, things that are already in your body. Standard 3D printers use a motor to melt plastic and cool it, but that wouldn’t work with the BioBot because the heat would kill the cells the printer uses. Instead, it uses an air compressor.

At least one company has built a desktop bioprinter, Cabrera said. Based in Boston, the company is called Seraph Robotics, though its website suggests that the company is more focused on traditional 3D printers for researchers, rather than bioprinters.

BioBots’ third cofounder is Sohaib Hashmi, currently an M.D./Ph.D. student at Penn.

As for Cabrera’s Ph.D.? He’s not so sure he needs it anymore.

Researchers are using these Philly-made ‘bioprinters’ to make hearts, stomachs