Sean Walker was poking around Eventbrite.com a few weeks ago, looking for interesting technology and medicine events. When he stumbled on the Independence/Jefferson Health Hack, he figured he’d give it a go.

The Delaware resident, 24, had no idea he’d walk away from the hackathon a winner in the weekend contest’s Wearables category.

Inadvertently, he did just about everything he could to not impress the judges, from oversleeping both days, to wearing an old T-shirt and lacking a PowerPoint presentation or business model. But his idea was so good, that in the end, none of that mattered.

His grand idea? Customizable prostheses for active amputees.

He’s compared the logistics of his prototype to that of a car: Both have versions of a frame, an interior, suspension and tires. The frame is the actual prosthetic socket that everything attaches to. Comfort is important, so the liner that touches the skin is akin to a car’s interior. “A Ferrari’s no good if the interior feels like sitting on a nail bed,” he said.

Then the suspension aspect allows for adjusting to conditions and giving support. One of his previous jobs as a lacrosse-stick maker helped him figure out how to mimic webbing that works like an Achilles tendon to reduce stress on the leg. And then there are the tires, which would be the feet.

The magic is in the feet. “You can break down the foot into individual components that can be adjusted and modified,” Walker said. “The whole encompassing idea is to break it down into easily made parts, with one socket, so you don’t have to worry about carrying around 15 legs.”

Active amputees, he said, often have several different leg models for various athletics.

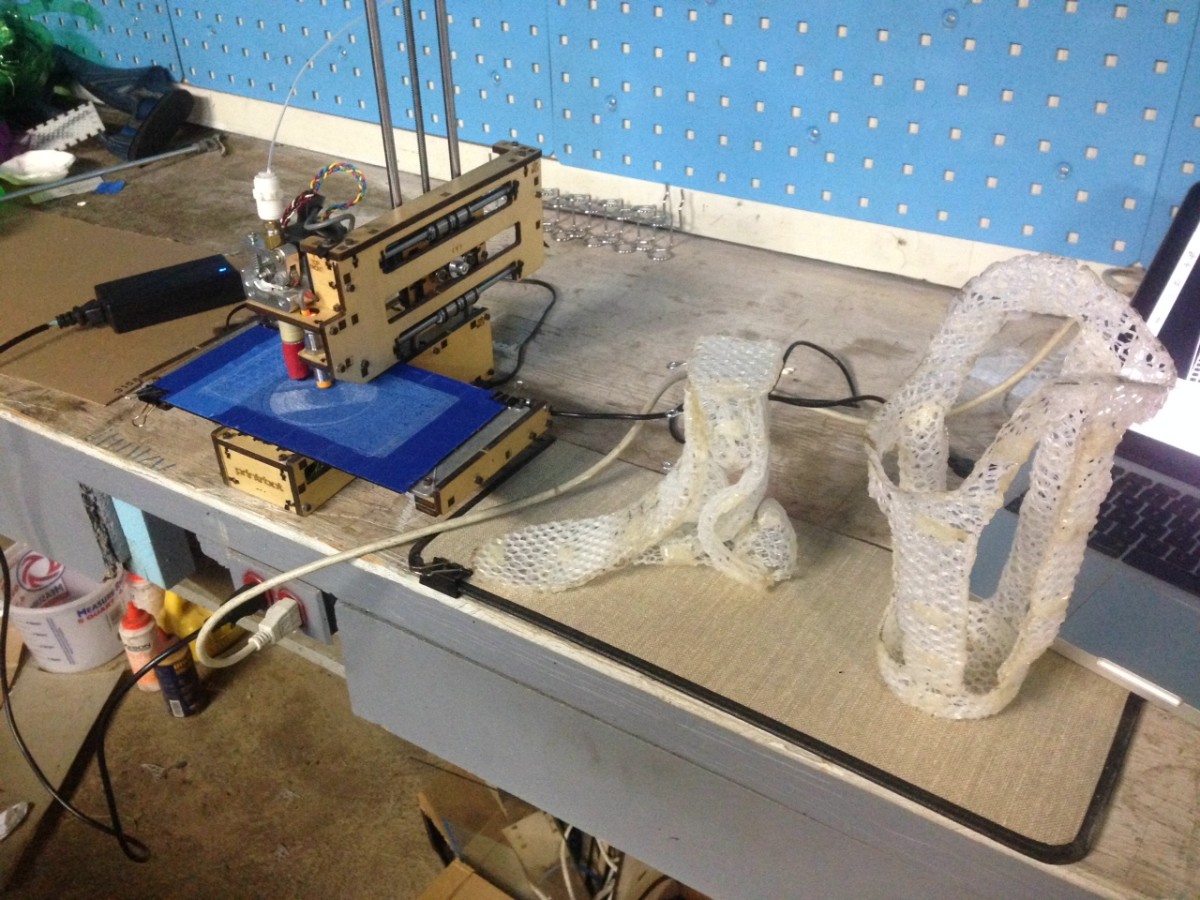

Walker, who works in a prosthetics lab and is an aid at a physical therapy clinic, made all of the parts with a 3D printer. “It’s all 3D-printing plastic,” he said. “Nothing strong or fancy.”

As a winner of the hackathon, he received $5,000, access to Microsoft business software that offers help from entrepreneurs and mentors, a three-month expert membership to makerspace NextFab in Philadelphia and a spot at The Center for Health Care Innovation at Independence Blue Cross incubator. He hopes to further develop his idea and is also starting to work on cosmetic covers for prostheses. He’s developing his own brand, Blue Collar Bionics, too.

“I want to take therapy equipment,” he said, “and make it more fun.”

Before you go...

To keep our site paywall-free, we’re launching a campaign to raise $25,000 by the end of the year. We believe information about entrepreneurs and tech should be accessible to everyone and your support helps make that happen, because journalism costs money.

Can we count on you? Your contribution to the Technical.ly Journalism Fund is tax-deductible.

Join our growing Slack community

Join 5,000 tech professionals and entrepreneurs in our community Slack today!