This editorial article is a part of Technical.ly's Healthcare Technologies Month of our editorial calendar.

Marvin Weinberger has created survival-focused products before, but the latest invention from the mind of the Havertown-based entrepreneur and inventor is an especially timely one: a DIY device that can sterilize masks, called the LightBox IR.

On March 26, the City of Philadelphia asked for donations of personal protective equipment after the growing number of COVID-19 hospitalizations in the area caused Philly hospitals to run low on medical supplies. Weinberger’s LightBox would allow masks to be sterilized of the virus so they can be reused instead of being thrown away.

It’s an inexpensive and simple solution with no fancy electronics that people can put together on their own, he told Technical.ly.

“Ideally, every electronic and electrical component will be readily available from Amazon to facilitate the DIY construction,” Weinberger said. “For most handy people this should be a quick and affordable build.”

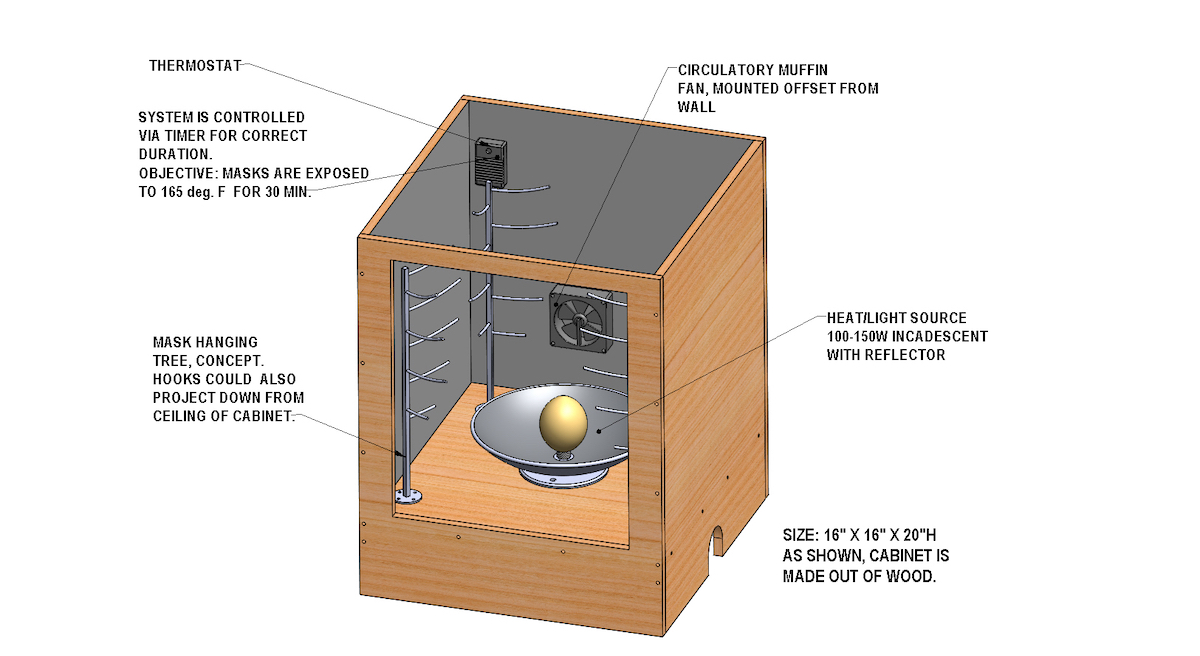

A larger version of the device would be made of a soft pretzel warmer with rotating arms, a heat lamp, a fan and aluminum foil that would line every surface. The smaller scale model of the device Weinberger recently came up with is a one-foot cube that may be able to disinfect six to 10 masks at a time and could be made out any heat resistant material, according to the inventor.

“The reason we are sticking with heat is that all you have to do is ensure that the chamber stays at the set temperature,” Weinberger said. “With UV, every surface would have to be equally exposed to the UV light for the 30-minute duration and that means you are limited to how many masks you can disinfect at a time.”

Studies show heat kills viruses very effectively. Data from N95DECON, a site compiling scientific studies on mask decontamination from scientists at Stanford University and other universities, said temperatures from 60 to 75 degrees Celsius (or 140 to 165 degrees Fahrenheit) will kill the virus on the surface of a mask after 30 minutes of heat exposure.

Weinberger said on Thursday that he hopes to have the design finalized within the week. New Jersey-based company, J&J Snack Foods, is providing the soft pretzel warmers for the larger version of the device that could disinfect dozens of masks at a time. Weinberger said he’s had preliminary conversations with makerspace NextFab about building simplified versions of the LightBox for people who want them immediately.

A mockup of the exterior of the LightBox IR. (Courtesy image)

Along with volunteers such as local engineers Edward Polkowski and Erich Wagner, who are assisting with the build and design of the box, and Dr. Basil Harris, whose 2017 Tricorder XPrize-winning device is currently being tested for FDA approval, Weinberger is “just going to continue to improve the design and get it out there,” he said.

The first goal is to ensure masks are completely usable and undamaged after 30 minutes in the LightBox. To achieve that, Weinberger is currently looking for a manufacturer to produce finished units at scale so they can then be distributed — at no charge — to local hospitals, nursing homes, fire stations and more, as well as a medical lab that will test the device’s ability to kill the virus. Reach out to marvin@innovationfactory.com to offer support.

_

Update (4/13/20, 12:52 p.m.): Indeed.

Damn this just … fits. https://t.co/knLz7uCnEe

— Nerd and Dad (@NerdyDad91730) April 13, 2020

Join the conversation!

Find news, events, jobs and people who share your interests on Technical.ly's open community Slack

Philly daily roundup: Women's health startup wins pitch; $204M for internet access; 'GamingWalls' for sports venues

Philly daily roundup: East Market coworking; Temple's $2.5M engineering donation; WITS spring summit

Philly daily roundup: Jason Bannon leaves Ben Franklin; $26M for narcolepsy treatment; Philly Tech Calendar turns one