Personal protective equipment like face masks, gloves, and gowns are vital for ensuring frontline health care workers’ safety each time that they step into a clinical setting, especially amid the COVID-19 pandemic. However, viruses and bacteria love to stick to these surfaces—meaning they’re effectively single-use items.

That’s created a new form of pollution. According to the World Economic Forum, a Geneva, Switzerland-based organization, if every person used a single-use face mask once a day for a year, it could create an additional 66,000 tons of contaminated waste in our oceans. And that’s just in the United Kingdom.

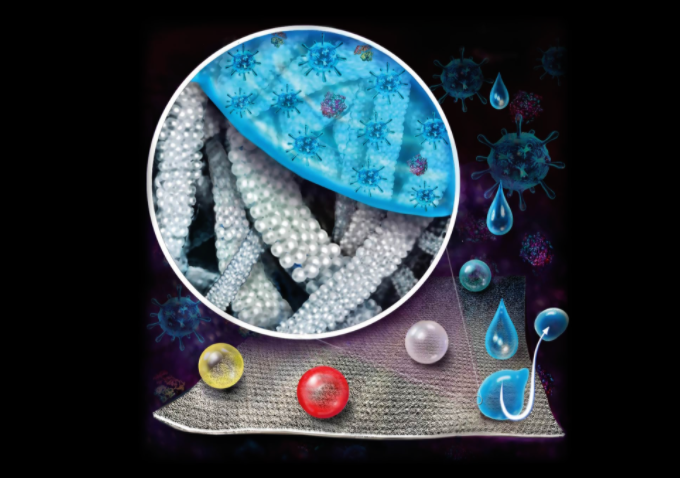

Researchers at the University of Pittsburgh may have devised just the right fix: a new textile coating that can not only repel typical dangerous hospital fluids, like blood and saliva, but even bacteria and viruses.

That way, health care workers could wash and reuse their face masks many times over, rather than instantly tossing them. Their ultimate goal is to prove that the material can also ward off SARS-CoV-2, the coronavirus that causes COVID-19. They published their findings in the peer-reviewed journal ACS Applied Materials and Interfaces on April 22.

From blood to viruses

Ten years ago, the research team began working on their superhemophobic (hemo, meaning blood, and phobic, meaning afraid) textile coating that could repel blood. But about a year ago, as if the scientists had a crystal ball, they shifted their focus toward a virus-repellent component, just before the devastating global pandemic broke out.

Because blood contains a whole slew of proteins, they wondered if the coating could make viruses slide right off of treated surfaces, as well. “Viruses are wrapped in an outer membrane of proteins, so then we thought maybe [the coating] could repel viruses,” said Anthony Galante, a Ph.D. student in industrial engineering and the lead author of the paper.

To test out that theory, he and his co-authors applied their coating to swatches of fabric and studied the number of infectious viruses that cling to the surface. They decided to study two kinds of adenoviruses that cause respiratory illness and conjunctivitis, also known as pink eye.

But because viruses are far too small to see with the naked eye—SARS-CoV-2, for example, is about 120 nanometers in diameter, or about 48 times the size of a strand of DNA—they had to indirectly measure them through a colony-forming unit, a common tool in microbiology labs for measuring the living things in a sample.

So, Galante explains, the researchers took liquid from the surface of their fabric and injected it into human lung cells in the lab. “And then these lung cells developed plaques, which are basically like a lung infection,” he says. “And then we count the plaques.” After six to seven days of incubation, the treated samples exhibited a decrease in infectious viruses of 99.2 percent and 97.6 percent for the two adenoviruses.

Durability matters

But to use the coating for reusable masks and gowns, the fabric must be exceptionally durable. Through ultrasonic washing tests—a process that uses ultrasonic waves to agitate a liquid, sort of like an electric toothbrush—the researchers found that the treated textile could endure 100,000 of these cycles. In another experiment, the scientists physically scraped at the material with a razor blade, yet it remained intact.

For their coating, the researchers decided to use polytetrafluoroethylene (PTFE), a polymer commonly used in Teflon pans. To coat fabric samples, they used a process called drop-casting to cover the material with droplets from a syringe. When they scale the concept up, Galante believes it will be easy to spray or dip the fabrics into the solution for mass production.

It’s the first time that scientists have proved a coating can repel viruses, Galante says, but the team will have to conduct further work to test out their design against SARS-CoV-2. Their lab isn’t certified at the biosafety level required to handle samples of the novel virus—however, other labs on campus working on a potential vaccine are certified. It’s a matter of waiting for a partner lab to have time and space for the fabric testing.

But as the coating stands now, health care workers could use it in place of regular personal protective equipment. From a practical standpoint, though, it could be confusing to track how many times the masks and gowns have been washed, if the equipment is only rated for, say, 20 to 50 uses.

Paul Leu, associate professor of industrial engineering at Pitt’s Swanson School of Engineering and one of the researchers involved with the work, says that his group is in talks with UPMC Children’s Hospital of Pittsburgh to learn how they do it.

“I would guess that each piece of clothing has some sort of unique identifier on it, maybe some sort of barcode or something, so that you can kind of scan it and then you would know, ‘oh yeah, maybe this is wash cycle number 10 for this piece of clothing,’” he says.

Medical sustainability

Leu hopes that the coating will usher in a wave of sustainability in the medical field. In Europe, he says, it’s already common to see reusable medical textiles. That’s not only beneficial for the environment, but eases the strain on manufacturers who cannot keep up with the demand for more masks, gowns, and gloves. “A lot of the single-use or disposable medical textiles are a really heavy burden on the supply chain, and manufacturing hasn’t really been able to ramp up to meet this demand,” he said.

And from a cost standpoint, there are clear savings. Leu didn’t offer an exact cost per mask treated with the virus-repellent coating—because the university has not yet licensed the technology for mass production—but he does say that, over time, hospitals could see savings of 50 percent over the course of a mask’s lifetime. In addition to hospitals, the team is in talks with a textile manufacturer in Colombia, as well as Gap, the clothing company, to sell their textile.

Only a vaccine will truly bring our lives back to some semblance of normalcy, Leu says, but improved, reusable masks could be a near-term game-changer for anyone working with the public during the pandemic.

“This could potentially help health care workers or people that work in high-risk environments…like a meatpacking factory or in restaurants,” Leu says. “Just having better protection, you know, can make a very big difference for people.”

Join the conversation!

Find news, events, jobs and people who share your interests on Technical.ly's open community Slack