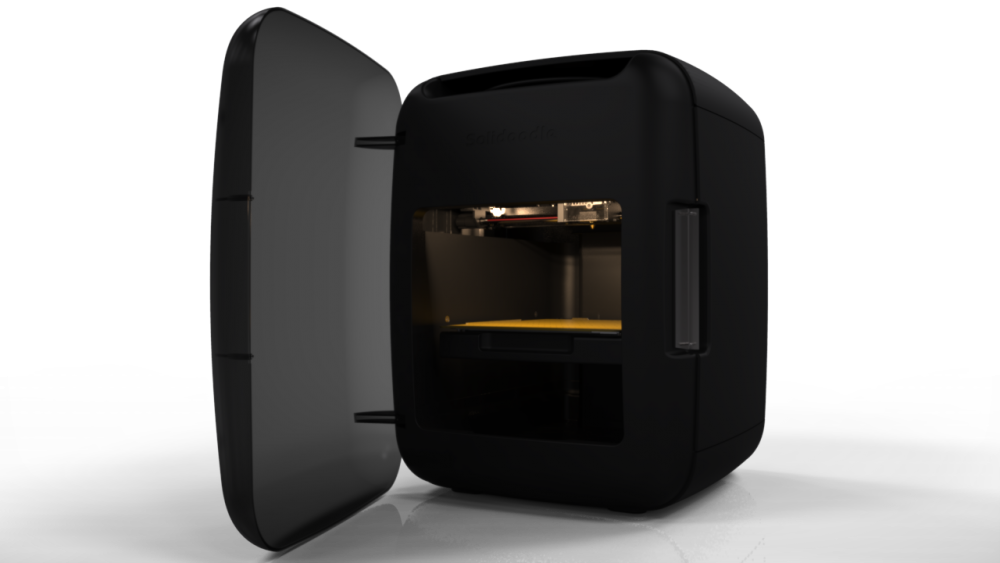

The Solidoodle Press represents a whole new phase for the 3D-printing company, CEO and founder Sam Cervantes explained to Technical.ly Brooklyn.

Here’s why.

The assembly line for the Press is set up to make 500,000 units, whereas the company would previously produce closer to 10,000 units. “It’s a paradigm shift for the company,” Cervantes said.

The move could be a big deal for Brooklyn’s fast-growing additive manufacturing ecosystem.

Cervantes told us in a recent phone interview that the Carroll Gardens 3D-printer maker is moving from low-volume manufacturing techniques (such as 3D printing all of its plastic parts) to high-volume techniques — that is, injection molding. This allows Solidoodle to make a better product, at scale, for a better price ($499, if you order one now).

The advantage of injection molding, Cervantes said, is that you can make high-quality parts at an excellent price. The problem is that any changes on the fly are practically impossible, since a change can delay production for a full month.

###

The Solidoodle Press is late to reach those that preordered it, however, as explained by this post.

“After testing the first few units off the assembly line, we decided to make an additional round of tooling modifications to ensure quality, reliability and ease-of-use,” Cervantes told us via email, in advance of our call. “Unfortunately, these modifications took more time than anticipated. The great news is that we’ve now cleared the hurdle — all tooling modifications are now complete and we’re seeing units roll off of the assembly line and we expect to begin shipping very soon.”

Cervantes said the company did its first round of experimentation with injection molding with the Solidoodle 4. Four parts on that machine were mass produced. On the Press, it’s all the plastic parts.

Cervantes described the previous iterations of the machine as prototypes made 10,000 at a time. Now Solidoodle knows what to make.

Cervantes said, price aside, there are two other aspects of the Press that will make a difference for users.

- A higher quality build, which is important for a device where stability matters.

- A built-in auto-calibration system, to check and recheck for print quality.

The Solidoodle Press will be built in China, tested and shipped to consumers from Brooklyn. The Brooklyn factory will continue to make the larger Solidoodle Workbench, Cervantes said. By our count, Solidoodle is the tenth largest tech company in Brooklyn.

Join the conversation!

Find news, events, jobs and people who share your interests on Technical.ly's open community Slack