This editorial article is a part of Technical.ly's Healthcare Technologies Month of our editorial calendar.

The COVID-19 crisis brought a shortage of ventilators that can help people battling the lung condition caused by the disease and led to a dire puzzle that leaders in the government and healthcare system are working to solve: how to acquire enough ventilators so that doctors don’t have to face the choice of refusing the machine to someone who needs it.

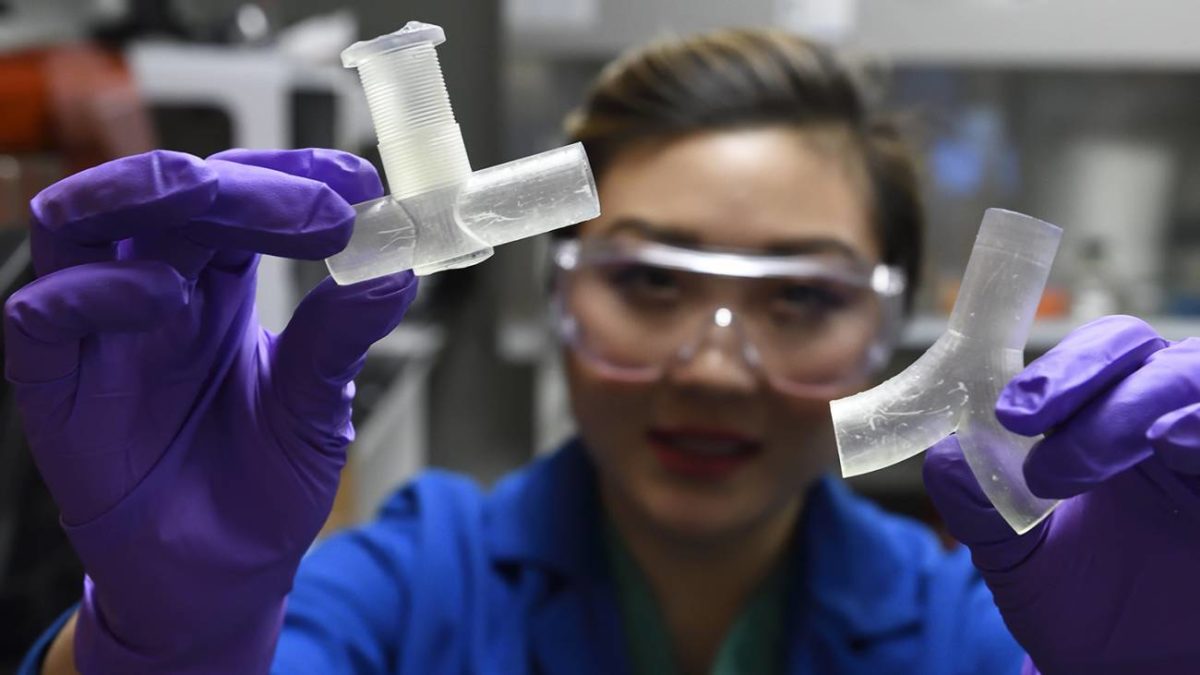

At Johns Hopkins University in Baltimore, a team of nearly 30 engineers and medical experts came together to create a missing piece that allows hospitals to tap into existing resources: The team is developing a splitter device that could allow a single ventilator to treat multiple patients. Team members said the devices are designed to be 3D printed.

Amid a crisis where the search for materials has led to talk of tapping federal stockpiles and retooling car manufacturing giants, it’s a local-level solution.

“Making ventilators is complicated and expensive,” said Dr. Julie Caffrey, an assistant professor of plastic and reconstructive surgery at Johns Hopkins Medicine, who is heading up the medical side of the team. “Making a splitter — with some safety features — that can be deployed and produced using off-the-shelf things that are found in the hospital is ideal in this situation.”

Speaking with friends working on the front lines of healthcare in New York, Caffrey heard of the needs to increase ventilator capacity at the U.S. epicenter of COVID-19 cases. If the hospitals reached capacity, she thought about enabling the sharing of ventilators as a last-resort solution, but knew it was an area where there were some concerns among the medical community.

Her immediate thought: “If we can measure the amount of volume and the amount of pressure going to each patient, then we can fix this.”

She was soon in touch with former colleague Dr. Justin Sacks, who now leads plastic and reconstructive surgery at Washington University in St. Louis, and quickly, a broader team was formed, drawing experts in pulmonology, anesthesiology and critical care. For design and fabrication, another dozen raised their hand from the engineering world, including Hopkins’ engineering school, MICA professor Jenna Frye and the JHU Applied Physics Lab in Laurel.

“People have volunteered their time and skill to make this happen,” said Sung Hoon Kang, an assistant professor of mechanical engineering who is the head of the engineering side.

Supported with a grant from JHU President Ronald Daniels’ office, they moved through designing and rapid prototyping over two weeks across three labs. The clinicians who are part of the team helped ensure that devices would be usable in the clinic, and they tested at the Johns Hopkins Simulation Center, which is typically used for training.

Specifically, ventilators help to treat acute respiratory distress syndrome, which is the leading cause of death associated with COVID-19. Safety is key, and they have added multiple components to allow for this along the way. One consideration is to tailor it to what each patient needs. So they added a gate valve with allows clinicians to control air delivery and pressure after the airway has been split, said Helen Xun, a medical student who is serving as project coordinator. They also created adapters allowing clinicians to continue to monitor the pressure. Another feature they are developing is a filter that will prevent cross-contamination that further spreads the virus between patients. And it’s all designed to be easy for hospitals.

“It should take minutes to set up and be usable right away,” Caffrey said.

Christopher Shallal. (Photo by Will Kirk/JHU)

The team also had to ensure they were using materials that could both be 3D printed, and met the standards of the U.S. Food and Drug Administration, said Christopher Shallal, an undergraduate biomedical engineering student. Even the resin had to be the right choice to ensure it could be reused.

As they continue testing, the team is looking to continue collaborating with the FDA as it seeks approval for its features.

With an open-source design that the team plans to post on the web, a big focus has been on keeping the design user friendly and scalable so that most anyone with a 3D printer can make one — from a hospital with one onsite to a maker with a printer at a space or home. This could build on networks that have been printing face shields — like the one built locally by Open Works — or tap into communities around the country. They’re also planning to make the designs available for researchers who want to collaborate, or adapt the designs.

“We do think 3D printing is a great way to rapidly prototype and meet the urgent needs of … New York and other cities,” Xun said.

Join the conversation!

Find news, events, jobs and people who share your interests on Technical.ly's open community Slack

Baltimore daily roundup: The city's new esports lab; a conference in Wilmington; GBC reports $4B of economic activity

Baltimore daily roundup: Find your next coworking space; sea turtle legislation; Dali raided and sued

Baltimore daily roundup: Johns Hopkins dedicates The Pava Center; Q1's VC outlook; Cal Ripken inaugurates youth STEM center